Brushless Dc Motor Working Principle

Principles Of Operation Of Dc Electric Motors

Q Tbn And9gcreemxuffs23klndzaeij7zgao7 Aivnwsy4p8tz0on7eoptpob Usqp Cau

Brushless Dc Bldc Motor Working Principle Your Electrical Guide

Brushless Dc Motors Part I Construction And Operating Principles Edn

Brushless Dc Motor Working Principle Characteristics Advantages

Electrical Brushless Dc Motor Introduction Working And Applications

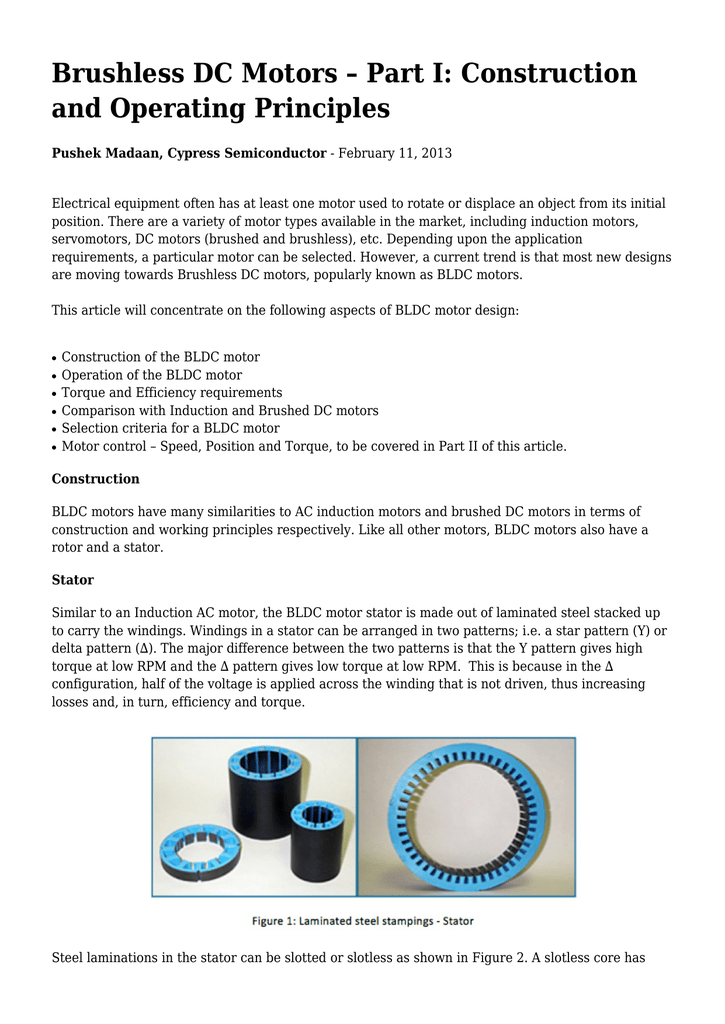

PRINCIPLES OF OPERATION OF SYNCHRONOUS MACHINES The synchronous electrical generator (also called alternator) belongs to the family of electric rotating machines Other members of the family are the directcurrent (dc) motor or generator, the induction motor or generator, and a number of derivatives of all these three.

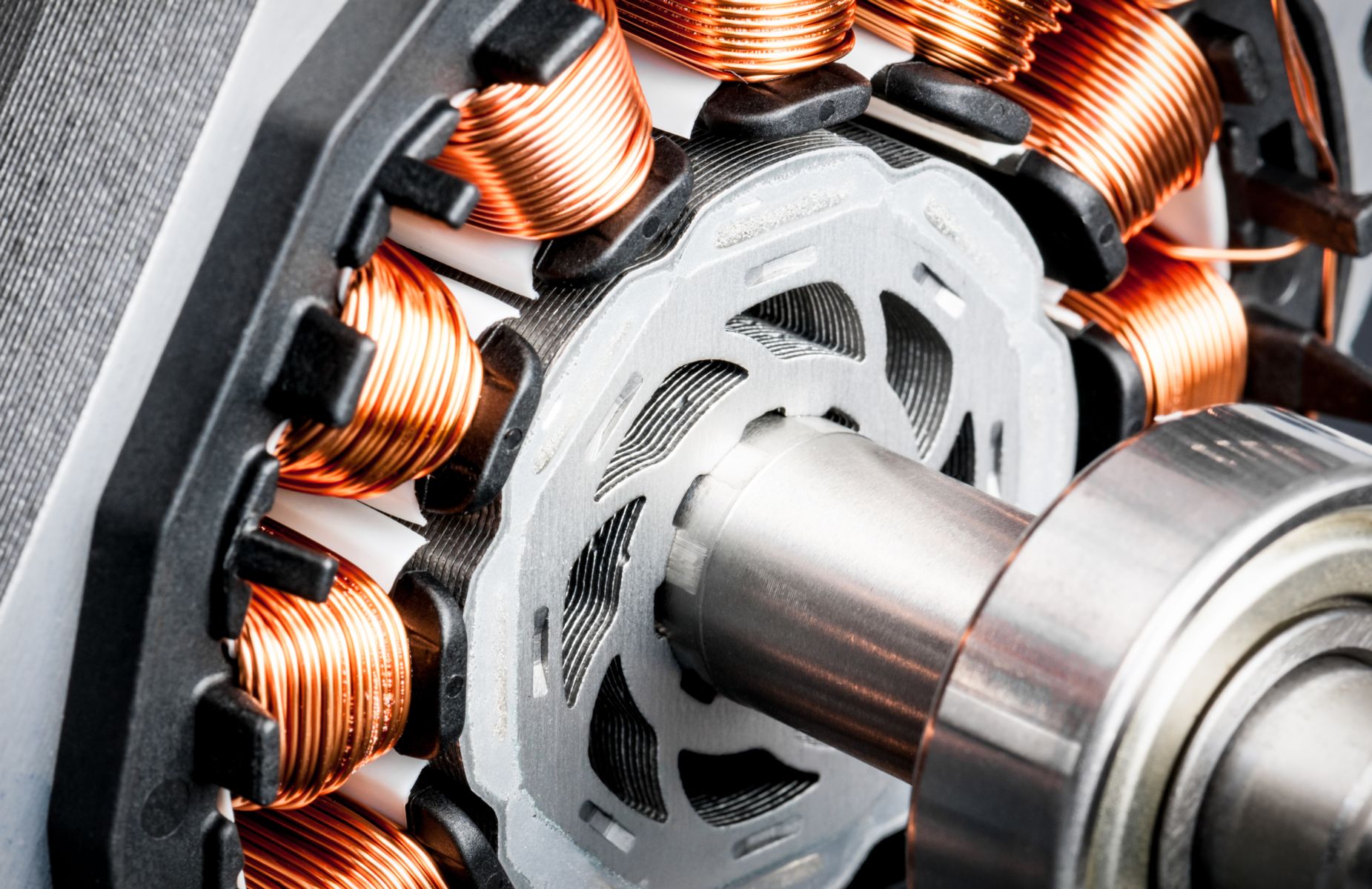

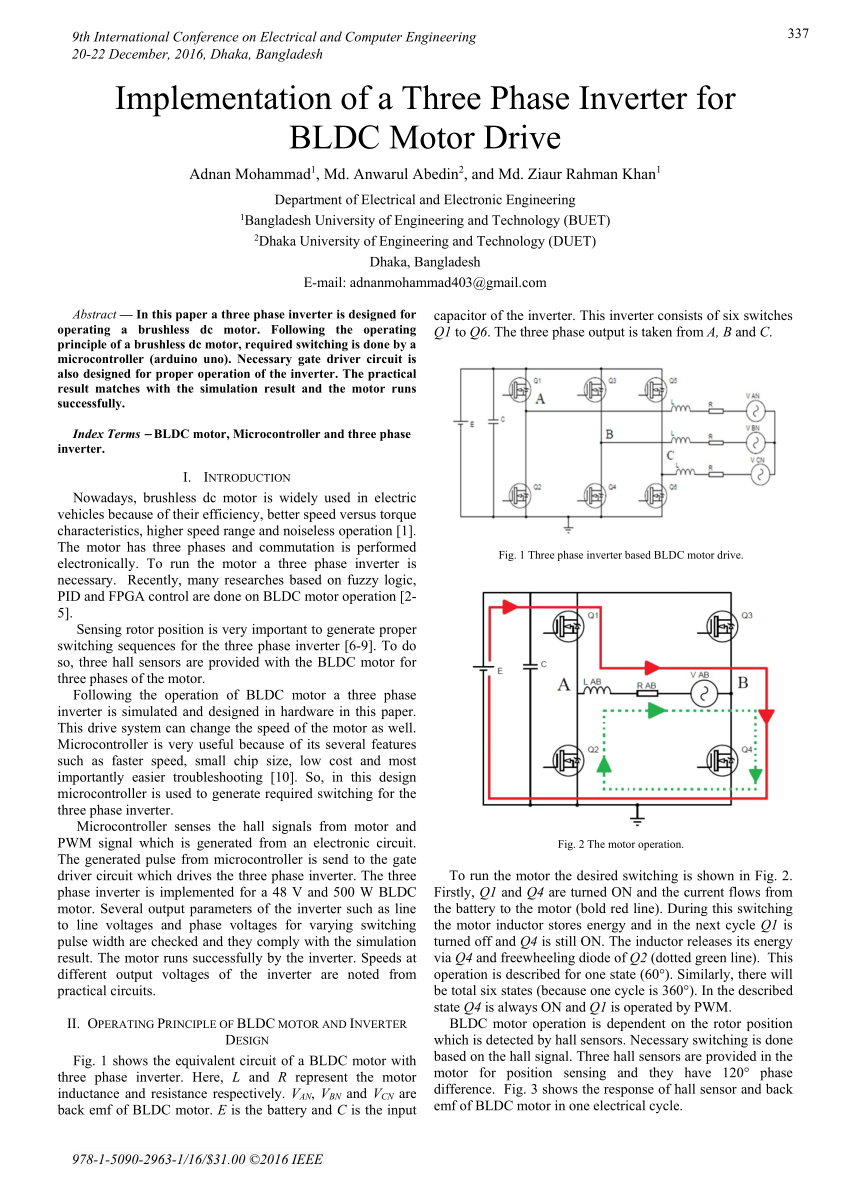

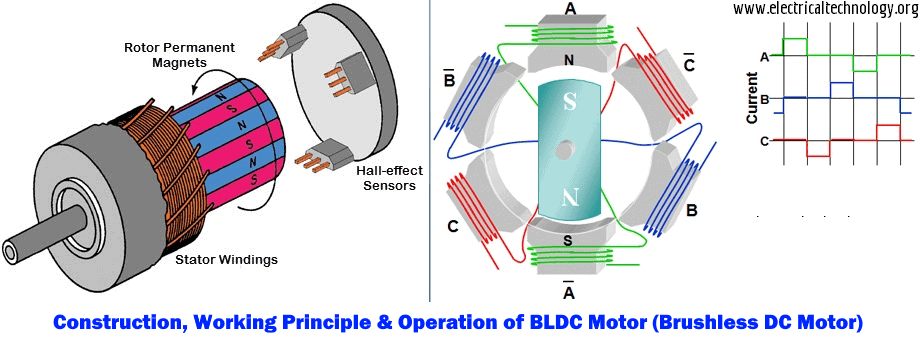

Brushless dc motor working principle. Read part 1 of this series on construction and operating principles here Having understood the construction and basic operating principle of BLDC motor in the first part of this article, it becomes important to understand the motor control options available for the reliable operation and protection of motorsBased on the functions served, motor control can be classified into following. • Find out more about our projecthttps//jaescompanycom/elearningphp• Here are some products installed by our technicianshttps//jaescompanycom/catal. A Brushless DC Motor is similar to a Brushed DC Motor but as the name suggests, a BLDC doesn’t use brushes for commutation but rather they are electronically commutated In conventional Brushed DC Motors, the brushes are used to transmit the power to the rotor as they turn in a fixed magnetic field.

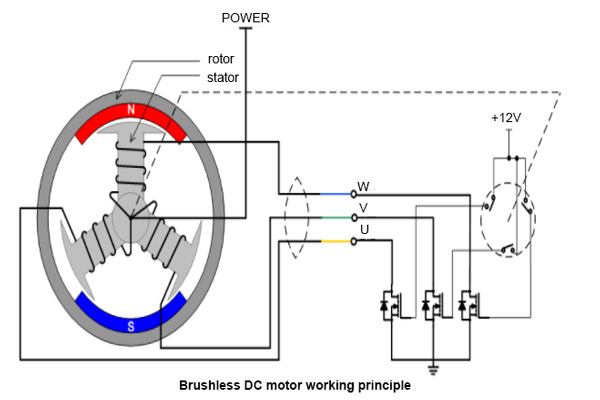

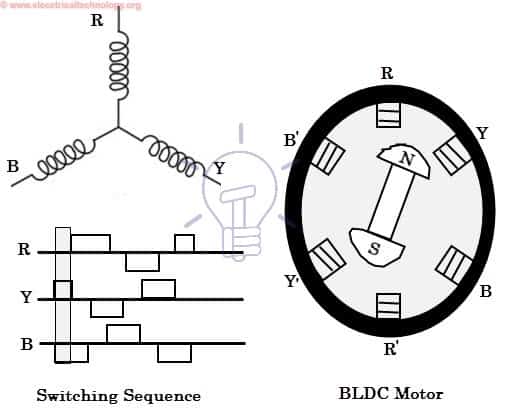

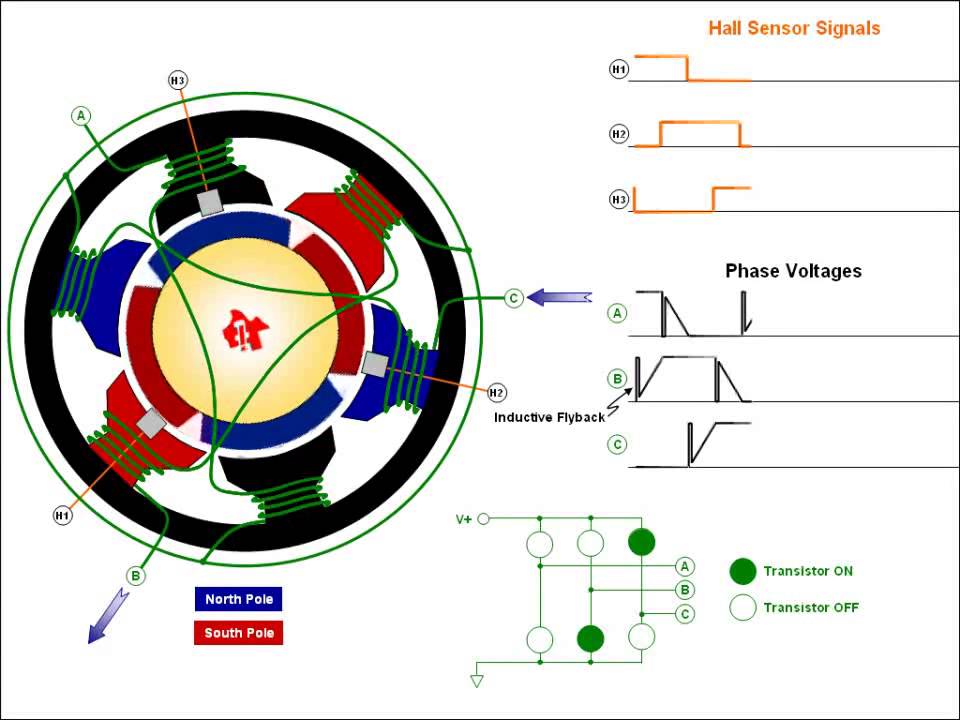

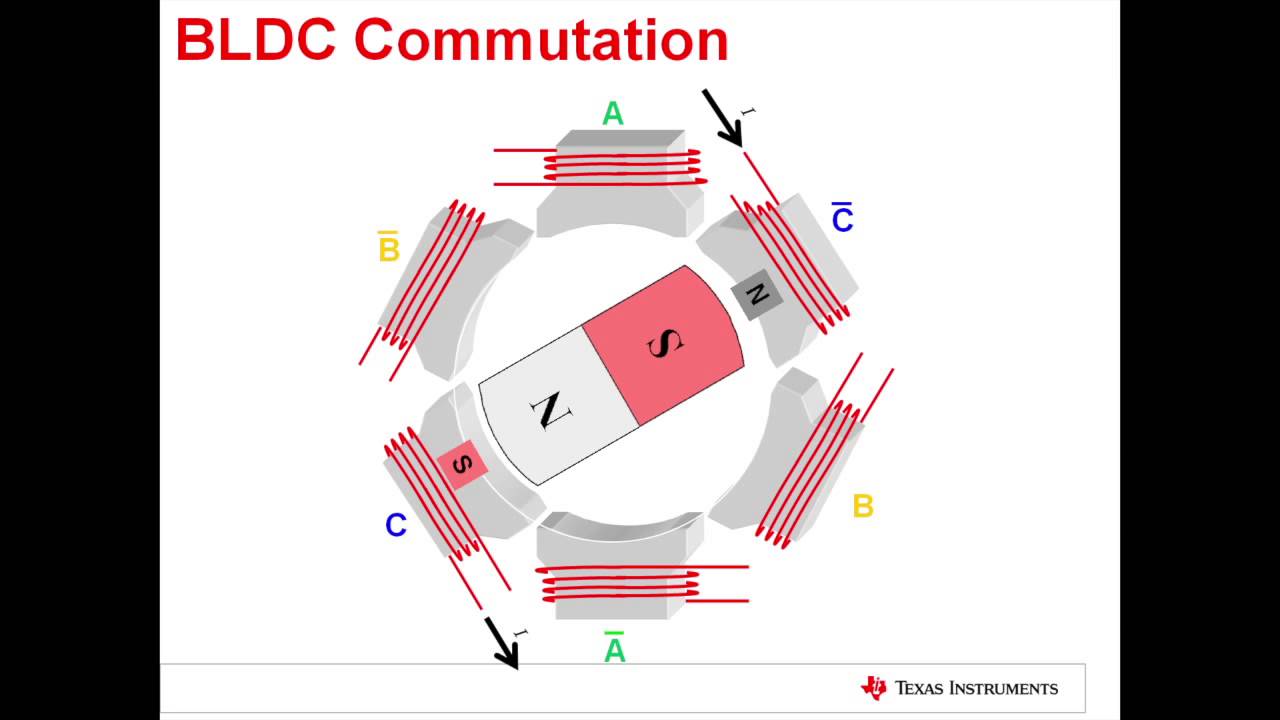

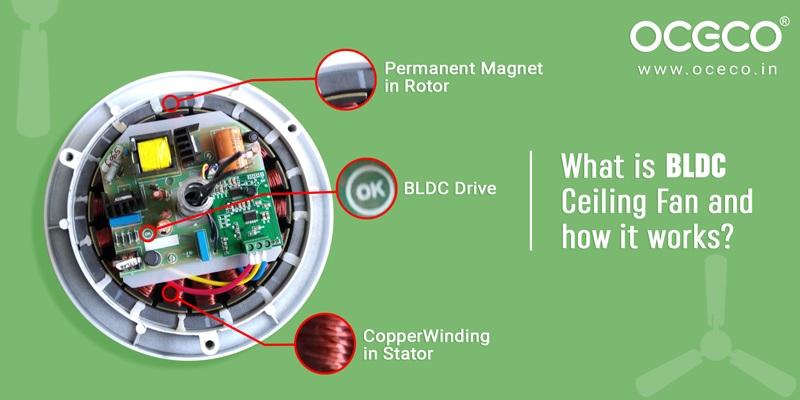

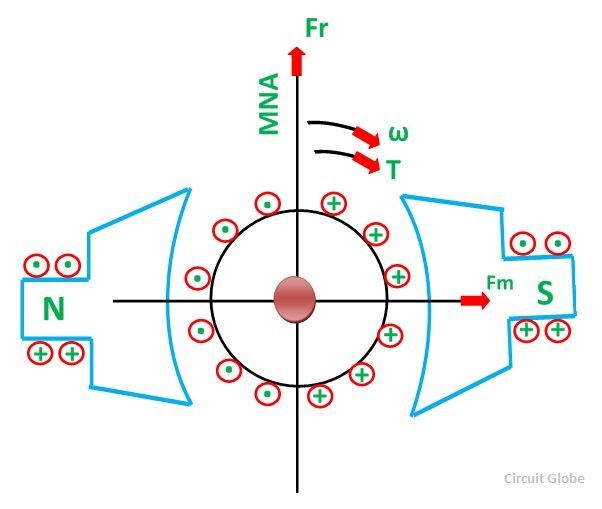

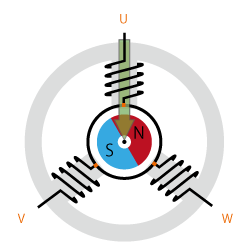

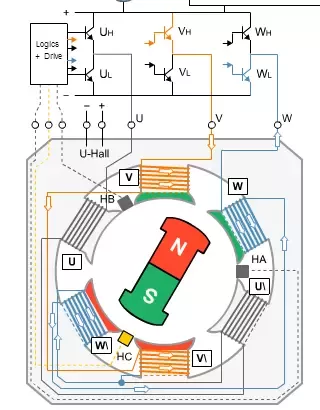

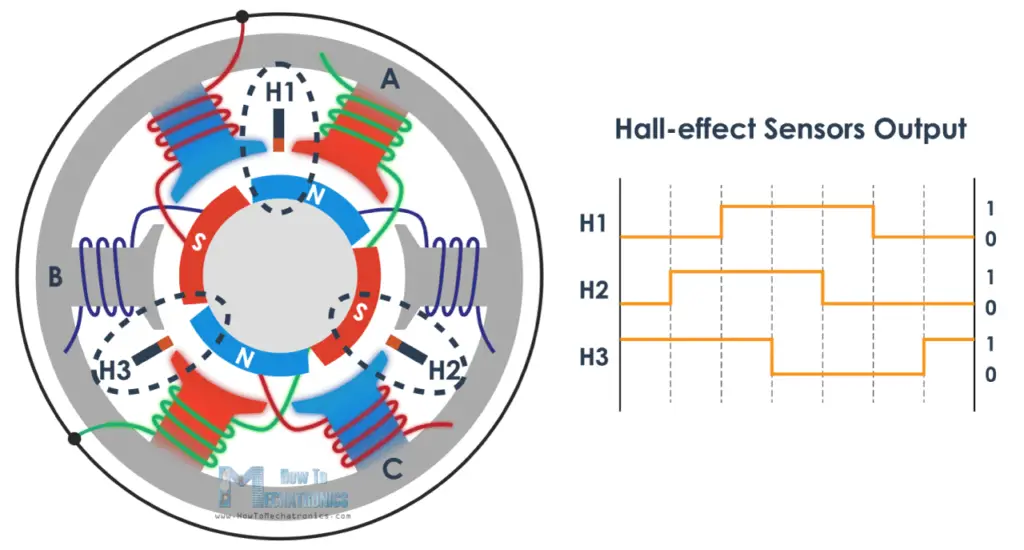

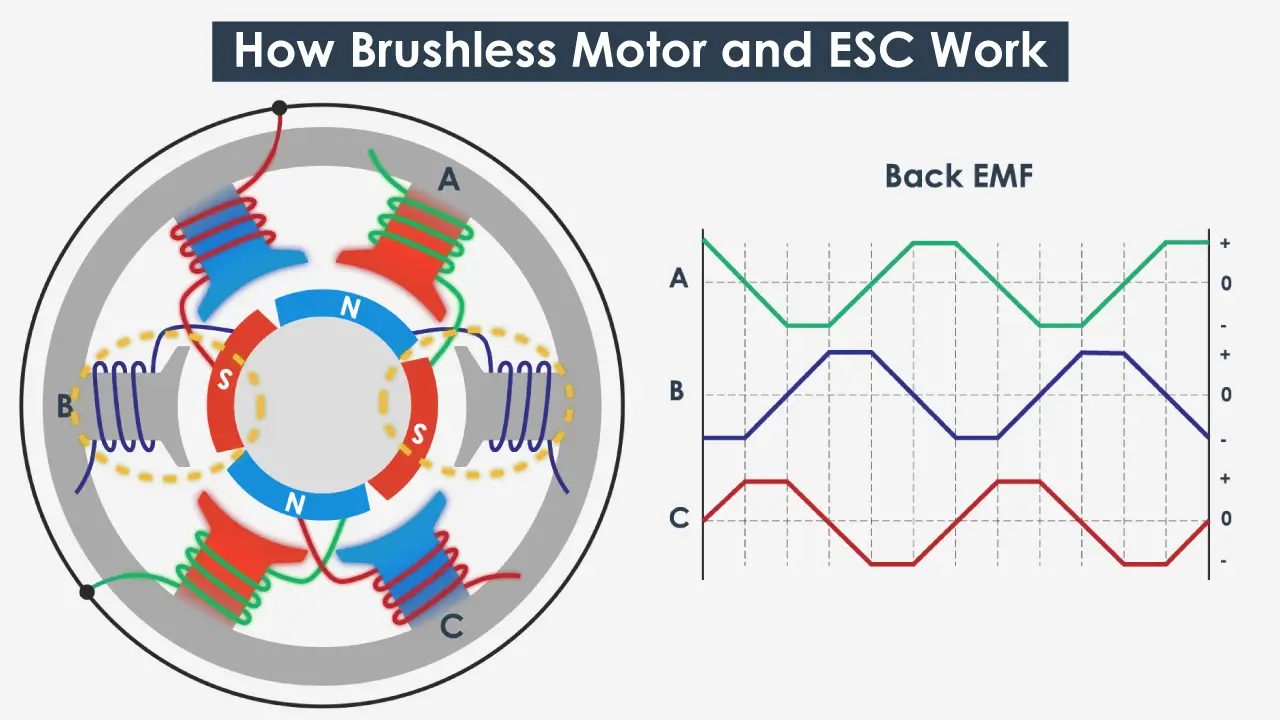

The principle of the working of a brushless DC motor is the mechanical torque development due to the interaction of the magnetic field produced by rotor magnets and stator coils. The brushless DC motor is driven by an electronic drive that switches the supply voltage between the stator windings as the rotor turns The rotor position is monitored by the transducer (optical or magnetic) which supplies information to the electronic controller and based on this position, the stator winding to be energized is determined. The following classification of brushless dc motors is also useful to understand the BLDC motor working principle One Phase, Onepulse Brushless DC Motor The stator of this motor has only a onephase winding which is energized by a transistor once per electrical revolution.

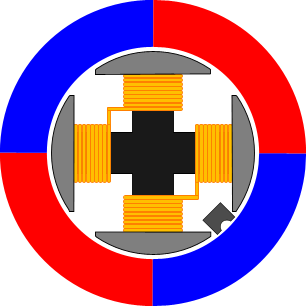

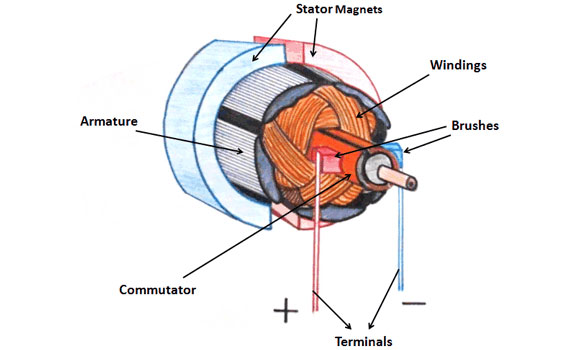

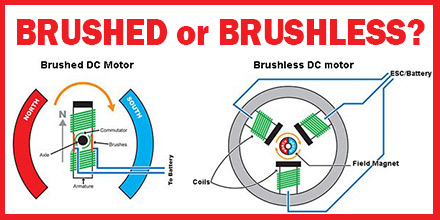

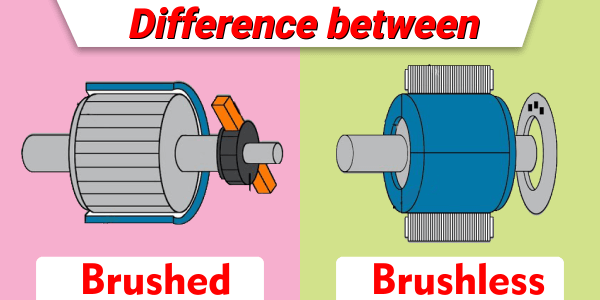

The basic working principle of a DC motor is based on the fact that whenever a current carrying conductor is placed inside a magnetic field, there will be mechanical force experienced by that conductor All kinds of DC motors work under this principle Hence for constructing a DC motor, it is essential to establish a magnetic field The magnetic field is established by using a magnet. Commutator (can be brushed or brushless, depending on the motor type) Field magnets (provide the magnetic field that turns an axle connected to the rotor) In practice, DC motors work based on interactions between magnetic fields produced by a rotating armature and that of the stator or fixed component A sensorless DC brushless motor controller. A brushless DC motor is essentially flipped inside out, eliminating the need for brushes to flip the electromagnetic field In brushless DC motors, the permanent magnets are on the rotor, and the electromagnets are on the stator A computer then charges the electromagnets in the stator to rotate the rotor a full 360degrees.

Working Principle of Brushless DC motor BLDC motor works on the principle similar to that of a Brushed DC motor The Lorentz force law which states that whenever a current carrying conductor placed in a magnetic field it experiences a force As a consequence of reaction force, the magnet will experience an equal and opposite force. Brushless DC motor (BLDC) and permanent magnet AC synchronous motors drives have many advantages such as high efficiency, small size, less rotor losses, and fast torque response over the induction motor drives Therefore, this chapter will focus on the design and implementation of a motor drive as well as its realization of control algorithm. Understanding the principle and application of high efficiency motors 1 of 3 A motor converts supplied electrical energy into mechanical energy Various types of motors are in common use Among these, brushless DC motors (BLDC) feature high efficiency and excellent controllability, and are widely used in many applications.

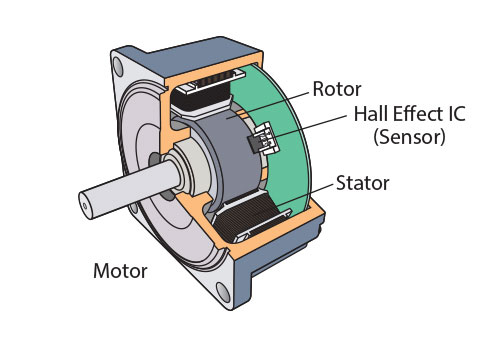

Working Principle of Brushless DC Motor As mentioned above a magnet with two poles is rotated around a permanent coil to produce electricity Detailed information is given in the below picture;. Brushless DC implementations can be sensorless or based on Halleffect sensors integrated into the motor (a third option is the use of an external angular position sensor) Sensorless systems reduce cost and require fewer interconnects between the driver module and the motor;. DC Motor Principle A machine that converts dc power into mechanical energy is known as dc motor Its operation is based on the principle that when a current carrying conductor is placed in a magnetic field, the conductor experiences a mechanical force The direction of the force is given by Fleming’s left hand rule.

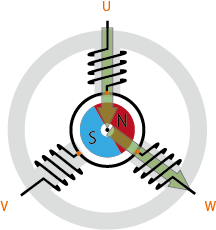

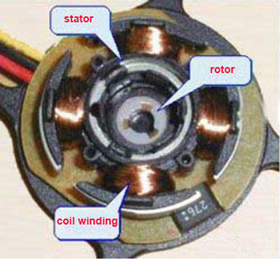

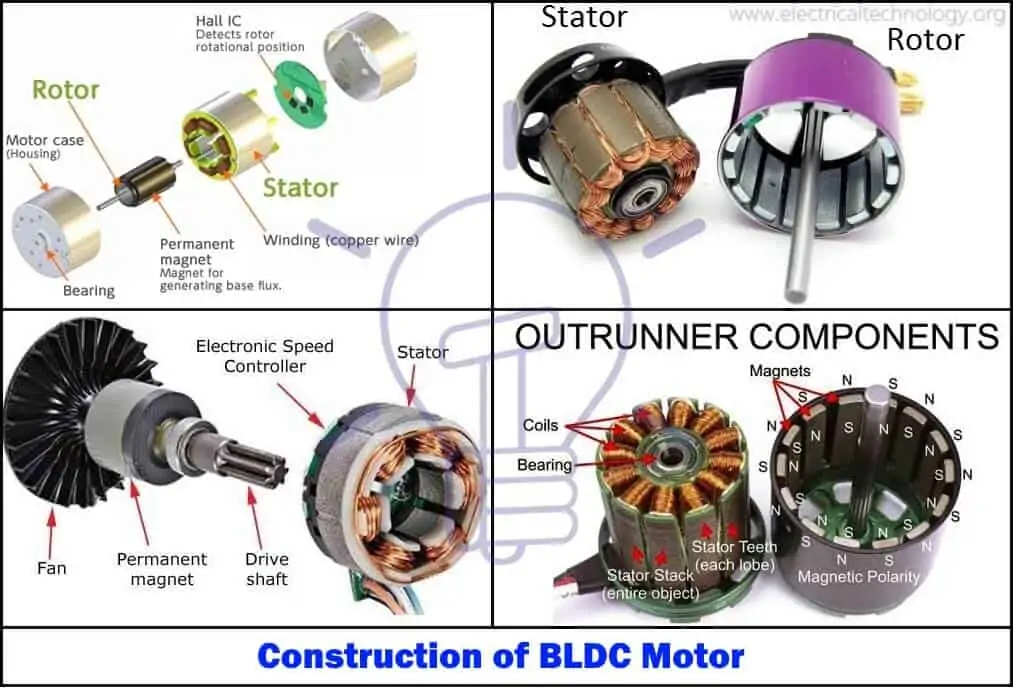

Read part 1 of this series on construction and operating principles here Having understood the construction and basic operating principle of BLDC motor in the first part of this article, it becomes important to understand the motor control options available for the reliable operation and protection of motorsBased on the functions served, motor control can be classified into following. A Brushless DC motor or BLDC motor is a type that is most suitable for applications that require high reliability, high efficiency, more torque per weight, etc This article explains about BLDC motors in details Construction of a BLDC Motor A commutatorbrushes arrangement helps in achieving unidirectional torque in a typical dc motor. As the name implies, Brushless motors differ from traditional DC motors in that they do not use brushes for commutating the electromagnets Instead, it is up to the motor controller to apply, in sequence, current to each of the 3 motor windings in order to cause the rotor to spin.

A brushless DC motor (known as BLDC) is a permanent magnet synchronous electric motor which is driven by direct current (DC) electricity and it accomplishes electronically controlled commutation system (commutation is the process of producing rotational torque in the motor by changing phase currents through it at appropriate times) instead of a mechanically commutation system. The work principle of the BLDC motor is similar to that of the brushed DC motor The brushed DC motor adopts the electric brush and the commutator to realize commutation of the current in the winding On the contrary, the BLDC motor realizes commutation of the winding current in the electronic way. Definition BLDC Motor also known as Brushless DC Motor is a motoroperated without brushes to overcome certain difficulties The basic difference between a brushed one and BLDC is operating with and without brushes A normal machine operates with brushes used to either collect or send current to the commutator.

A, Brushless motor works through the the alternating electromotive force of armature coil,by the commutator with brushes for the role, so that leads from the brush end into the DC when the force of the principle EMF direction is determined by the righthand (magnetic induction line to the palm of the hand, thumb pointing to the direction of conductor movement, the other four fingers pointing is the direction of the electromotive force induced in the conductor). The Working Principle of 48v Brushless DC Motor Due to the commutation of the brush, the magnetic field generated by permanent magnet steel and the magnetic field generated by armature winding is always vertical during the operation of the motor, so as to produce the maximum torque and make the motor run. BLDC BRUSHLESS DC MOTOR EVERYTHING YOU NEED TO KNOW !!!.

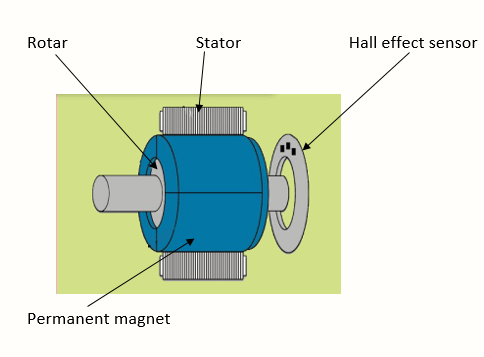

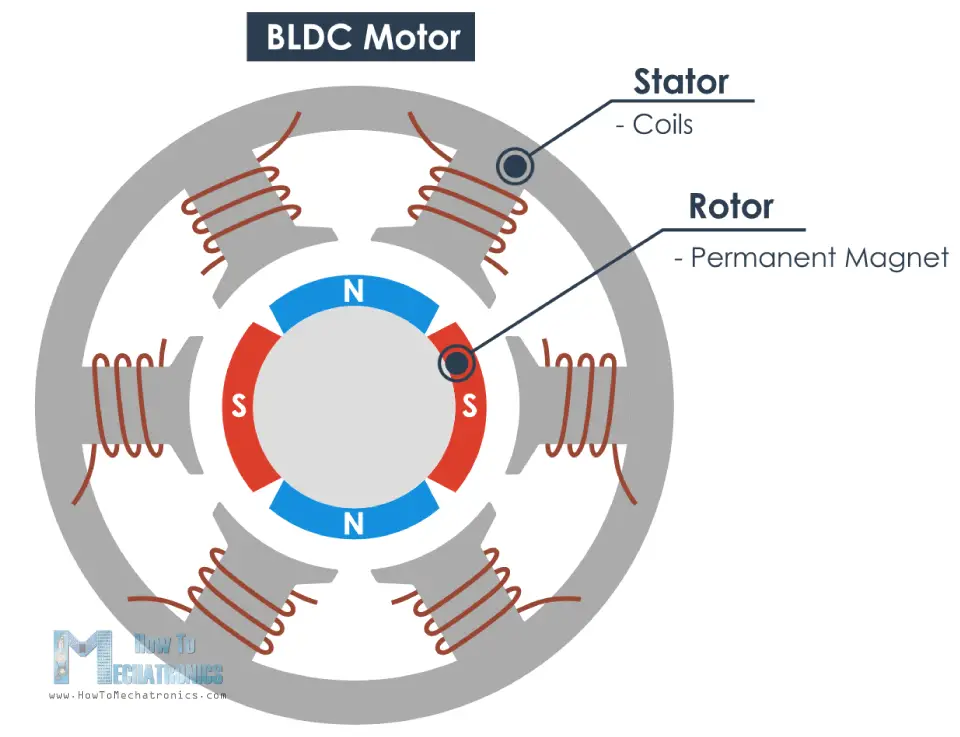

Ie, internal shaft position feedback In case of a brushed DC motor, feedback is implemented using a mechanical commutator and brushes With a in BLDC motor, it is achieved using multiple feedback sensors. How Does A Brushless DC Motor Work?. The armature which in the case of the brushed motor, rotates within the stator, is stationary in brushless motors and the permanent magnet, which in brushed motors is fixed, serves as the rotor in a brushless motor Simply put, the stator for brushless DC motors is made up of coils while its rotor (to which the motor shaft is attached) is made up of a permanent magnet.

Ie, internal shaft position feedback In case of a brushed DC motor, feedback is implemented using a mechanical commutator and brushes With a in BLDC motor, it is achieved using multiple feedback sensors. The working principle of the DC brushless motor is that the stator of the brushless DC motor is a coil winding armature, and the rotor is a permanent magnet If only a fixed direct current is applied to the motor, the motor can only generate a constant magnetic field, but the motor cannot rotate. The publish details the simple operational concept of brushless DC motors also known as BLDC motor In our standard brushed motors brushes are widely used to with the intention to switch the central moving rotor with regards to the surrounding stationery permanent magnet stator.

Working Principle of DC Motor An electromechanical energy conversion device will take electrical energy at the input and produces a mechanical energy at the output side There are three electrical machines that are extensively used for this task a DC motor, an induction or asynchronous motor and a synchronous motor. Brushless Direct Current (BLDC) motors are one of the motor types rapidly gaining popularity BLDC motors struction, working principle, characteristics and typical Brushless DC (BLDC) Motor Fundamentals AN5 DS005Apage 2 03 Microchip Technology Inc. DC Motors Principle of Operation Electric motors run by electromagnetism However, there are also other types of motors that utilize electrostatic forces or piezoelectric effect In a brushless motor, when electricity is applied across the motor termination, a current flows through a fixed stator field and is interacting with a moving.

Efficiency wise, brushless motors are typically 8590% efficient whereas a brushed DC motor is 7580% Windings are present on the rotor for a brushed motor as compared to in a stator for a brushless motor. The figure shown below is the working principle diagram of brushless DC motor, for the convenience of description, the stator coil center of the stator is connected to the power supply "POWER", each phase of the end is connected to the power tube, connect the power tube G with 12V when the position sensor is on, and the corresponding phase coil is energized. Brushless DC Motor The input of a brushless DC motor is current/voltage and its output is torque Understanding the operation of the DC motor is very simple from a basic diagram is shown below DC motor basically consists of two main parts So, this is the working principle of the DC motor Types of DC Motors.

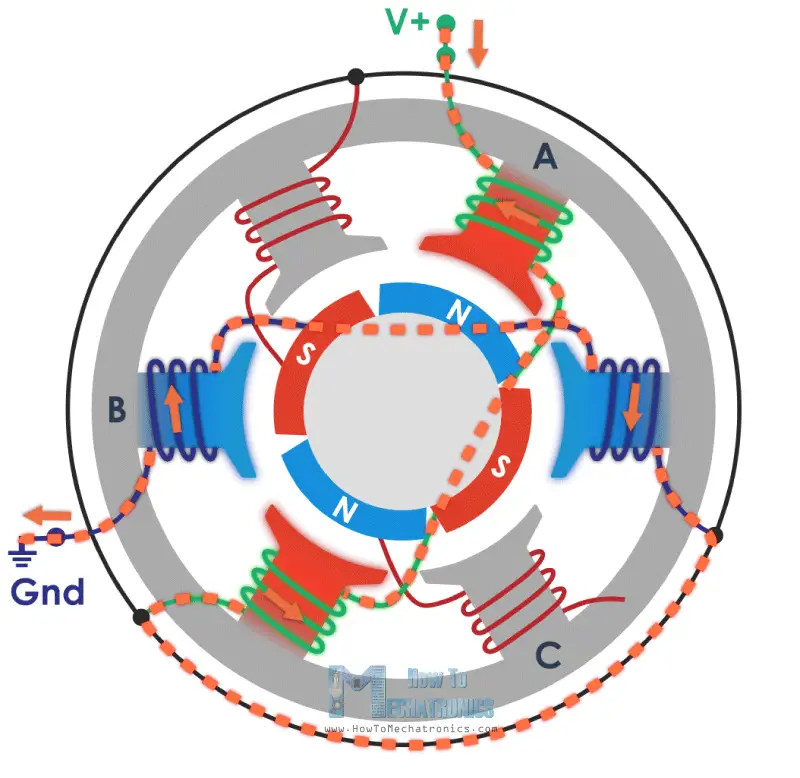

The basic working principle for the brushed DC motor and for brushless DC motor are same ie internal shaft position feedback Brushless DC motor has only two basic parts rotor and the stator The rotor is the rotating part and has rotor magnets whereas stator is the stationary part and contains stator windings. In order to make the operation more reliable, more efficient, and less noisy the recent trend has been to use brushless DC (BLDC) motors They are also lighter compared to brushed motors with the same power output This article gives an illustrative introduction on the working of BLDC motors. Principle of operation of a brushless DC motor A brushless DC motor avoids the need for a commutator and brushes by having its permanent magnets in the rotor Rotation of the rotor is maintained by detecting the position of the rotor magnetic poles and switching the electric current flow through the coils accordingly.

Help us to make future videos for you Make LE's efforts sustainable Please support us at Patreoncom !. The armature which in the case of the brushed motor, rotates within the stator, is stationary in brushless motors and the permanent magnet, which in brushed motors is fixed, serves as the rotor in a brushless motor Simply put, the stator for brushless DC motors is made up of coils while its rotor (to which the motor shaft is attached) is made up of a permanent magnet. Motor movement is controlled by means of carefully designed drive signals Compared to brushed motors, brushless motors offer improved reliability, longer life, smaller size, and lower weight.

A brushless DC electric motor (BLDC motor or BL motor), also known as electronically commutated motor (ECM or EC motor) and synchronous DC motors, are synchronous motors powered by direct current (DC) electricity via an inverter or switching power supply which produces electricity in the form of alternating current (AC) to drive each phase of the motor via a closed loop controller. If you're working on a project that has a moving part, you'll probably be looking for a motor to make that movement possible In this series, we explore the most popular types of motors that makers utilize First, we covered brushed DC motors Now, let's take a look at its close counterpart the brushless DC motor. A brushless DC motor (known as BLDC) is a permanent magnet synchronous electric motor which is driven by direct current (DC) electricity and it accomplishes electronically controlled commutation system (commutation is the process of producing rotational torque in the motor by changing phase currents through it at appropriate times) instead of a mechanically commutation system.

Best Motor Types to Build Wind Energy Turbine Some types of motors are more efficient than others With the same wind speed one can produce 10W. Working Principle of DC Motor An electromechanical energy conversion device will take electrical energy at the input and produces a mechanical energy at the output side There are three electrical machines that are extensively used for this task a DC motor, an induction or asynchronous motor and a synchronous motor. The working principle of the DC brushless motor is that the stator of the brushless DC motor is a coil winding armature, and the rotor is a permanent magnet If only a fixed direct current is applied to the motor, the motor can only generate a constant magnetic field, but the motor cannot rotate.

In order to make the operation more reliable, more efficient, and less noisy the recent trend has been to use brushless DC (BLDC) motors They are also lighter compared to brushed motors with the same power output This article gives an illustrative introduction on the working of BLDC motors. In a brushless DC motor (BLDC), you put the permanent magnets on the rotor and you move the electromagnets to the stator Then you use a computer (connected to highpower transistors) to charge up the electromagnets as the shaft turns This system has all sorts of advantages. Theoreticly rc brushless motor KV rating represents the speed at which the motor rotates for every volt applied to the motor For example if a motor is 2300kv with a 3S quadcopter battery motor applied to its ends then the motor will spin at 2600x1260 =32,760 rpm (Revolutions per minute number of turns in one minute), without propellers.

Brushless DC Outer Rotor Motor In the outer rotor motor, the winding locates in the core and is surrounded by the rotor The magnets trap the motor’s heat inside and do not allow it to dissipate from the motor We don’t usually use this motor, as it only at a lowerrated current and has a low clogging torque Advantages of the BLDC Motor. Principle of operation of a brushless DC motor A brushless DC motor avoids the need for a commutator and brushes by having its permanent magnets in the rotor Rotation of the rotor is maintained by detecting the position of the rotor magnetic poles and switching the electric current flow through the coils accordingly. A brushless DC motor, also known as synchronous DC motor, unlike brushed DC motors, do not have a commutator The commutator in a brushless DC motor is replaced by an electronic servomechanism that can detect and adjust the angle of the rotor A brushed DC motor features a commutator that reverses the current every half cycle and creates single direction torque.

Ie, internal shaft position feedback In case of a brushed DC motor, feedback is implemented using a mechanical commutator and brushes With a in BLDC motor, it is achieved using multiple feedback sensors. A DC motor is an electrical machine which converts electrical energy into mechanical energy The basic working principle of the DC motor is that whenever a current carrying conductor places in the magnetic field, it experiences a mechanical force Fleming’s lefthand rule and its magnitude decide the direction of this force. With the help of this information you can easily understand the BLDC motor working principle Unlike a conventional dc motor, a brushless dc motor has an “insideout” construction, that is, the field poles rotate and the armature is stationary The field poles consist of permanent magnets mounted on the inside of a steel cylinder and the armature is wound on a slotted laminated iron structure.

A brushless DC motor is essentially flipped inside out, eliminating the need for brushes to flip the electromagnetic field In brushless DC motors, the permanent magnets are on the rotor, and the electromagnets are on the stator A computer then charges the electromagnets in the stator to rotate the rotor a full 360degrees. The article How Electric Motors Work explains how brushed motors work In a typical DC motor, there are permanent magnets on the outside and a spinning armature on the inside The permanent magnets are stationary, so they are called the statorThe armature rotates, so it is called the rotor The armature contains an electromagnetWhen you run electricity into this electromagnet, it creates a. The working of DC motor is based on the principle that when a current carrying conductor is placed in a magnetic field, it experiences a mechanical force The direction of the mechanical force is given by Fleming’s Lefthand Rule and its magnitude is given by F = BIL Newton.

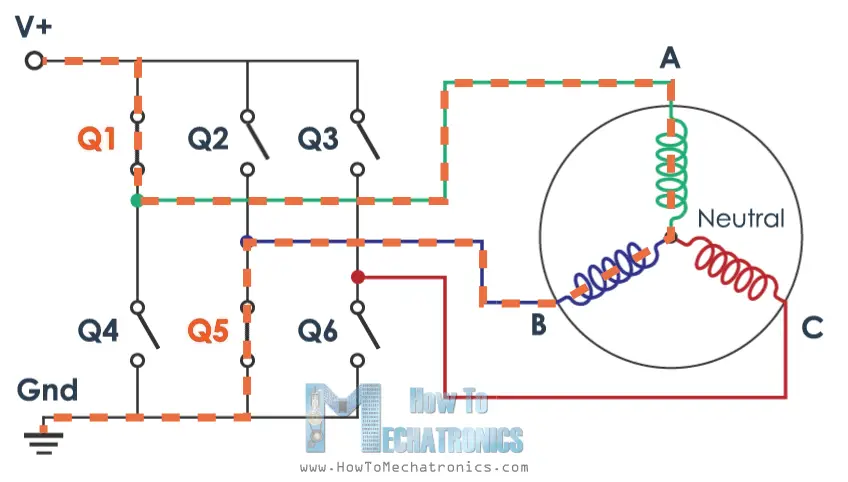

In a brushless DC motor (BLDC), you put the permanent magnets on the rotor and you move the electromagnets to the stator Then you use a computer (connected to highpower transistors) to charge up the electromagnets as the shaft turns This system has all sorts of advantages. BLDC Motor operation is based on the attraction or repulsion between magnetic poles Using the threephase motor as shown in figure below, the process starts when current flows through one of the three stator windings and generates a magnetic pole that attracts the closest permanent magnet of opposite pole. They can be somewhat complex, but highperformance integrated.

Working Principles and Operation The underlying principles for the working of a BLDC motor are the same as for a brushed DC motor;. Again, as implied by its name, brushless DC motors don't utilize brushes;. Brushless Permanent Magnet DC Motor • Brushless DC electric motor also known as electronically commutated motors (ECMs, EC motors) are synchronous motors that are powered by a DC electric source via an integrated inverter/switching power supply, which produces an AC electric signal to drive the motor – magnetic fields generated by the stator and rotor rotate at the same frequency – no slip • The stator consists of several coils which current is led through Creating a magnetic field.

A Brushless DC Motor, BLDC accomplishes commutation electronically using rotor position feedback to determine when to switch the current The BLDC motor is electrically commutated by power switches instead of brushes The structure of Brushless DC Motor, BLDC is shown in figure below. Read part 1 of this series on construction and operating principles here Having understood the construction and basic operating principle of BLDC motor in the first part of this article, it becomes important to understand the motor control options available for the reliable operation and protection of motorsBased on the functions served, motor control can be classified into following. Working Principle of brushless dc motor Posted by leafmotor on April 22, A, Brushless motor works through the the alternating electromotive force of armature coil,by the commutator with brushes for the role, so that leads from the brush end into the DC when the force of the principle.

Working Principles and Operation The underlying principles for the working of a BLDC motor are the same as for a brushed DC motor;.

Brushless Dc Bldc Motor Construction And Working Electricaleasy Com

China Golden Motor High Efficient Brushless Dc Motor Hpmkl kw Electric Car Motor China Brushless Motor 72v 96v kw Bldc Motor

Www Infineon Com Dgdl Infineon Motorcontrol Handbook Additionaltechnicalinformation V01 00 En Pdf Fileid 5546d4626bb628d7016be6a9aa637e69

Basics Of Brushless Dc Motors Bldc Motors Construction Working

Dc Motor Types Brushed Brushless And Dc Servo Motor Electronics Education Mechanical Energy Electrical Engineering

Brushless Dc Motors Gain In Popularity Ee Publishers

Brushless Dc Motor How It Works Ato Com

How Does A Brushless Electric Motor Work Howstuffworks

Brushless Dc Motors Part I Construction And Operating Principles

Brushless Dc Bldc Motor Construction And Working Electricaleasy Com

An Introduction To Brushless Dc Motors Motion Control Blog

How Brushless Motor And Esc Work Howtomechatronics

Operation Principle Of A Brushless Dc Motor A A Stator Winding Download Scientific Diagram

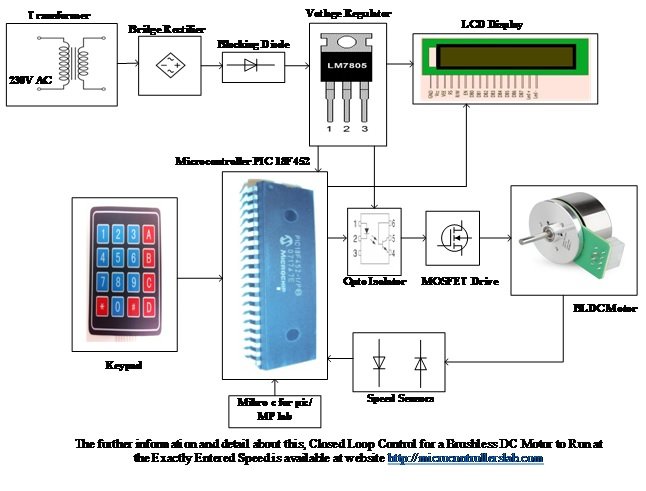

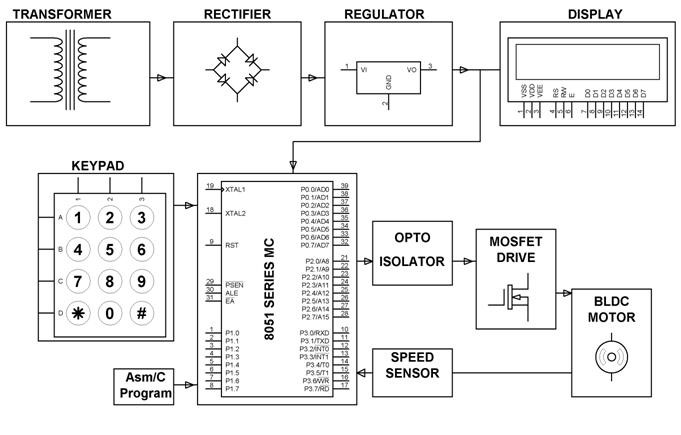

Bldc Motor Speed Control With Rpm Display System

Brushless Dc Motors And Brushed Dc Motors What Are The Differences Insight Solutions Global

Pdf Construction And Working Of Brushless Dc Motors Jyoti Dubey Academia Edu

How To Power And Control Brushless Dc Motors Digikey

Brushless Dc Motor Working Principle Gif Sticker Gif Gfycat

Switched Reluctance Motors And Brushless Dc Motor Operation Our Education

Brushed Vs Brushless Motors Operation Construction And Applications

Dc Motor Wikipedia

The Brushless Dc Motor And To Explain The Working Principle Programmer Sought

Brushless Dc Motors Introduction For Next Generation Missile Actuation Systems Outline Analog Devices

Closed Loop Control For A Brushless Dc Motor Using Pic Microcontroller

Brushless Dc Motors Introduction For Next Generation Missile Actuation Systems Outline Analog Devices

Q Tbn And9gct8yrmsg08m9qhkw2cvrflwxt1ebal0s Bexkjlsl3xojz3jyfp Usqp Cau

China Hpm5000l 5000w 5kw Inboard Marine Brushless Dc Motor For Electric Boat China Electric Motorcycle Motor 5kw Bldc Motor

Difference Between Brushed Motors And Brushless Motors Difference Between

How Brushless Motor And Esc Work Futurelab3d

Brushless Dc Motors Vs Servo Motors Vs Inverters

Permanent Magnet Brushless Dc Motor

What Is Brushless Dc Motor Bldc Construction Working

Brushless Dc Motors Introduction For Next Generation Missile Actuation Systems Outline Analog Devices

Unit 4 Brushless Dc Motor Outline Reference List To Probe Further Major Applications Basic Working Principle Illustrated A Typical Sample Configuration Ppt Download

The Basics Of Bldc Motors Elettroamici

1

How Do Single Phase Bldc Motors Start In Proper Direction Electrical Engineering Stack Exchange

Brushless Dc Motor Construction Working Principle And Advantages

Dc Motors

Hdd Bldc Motor

Electrical Brushless Dc Motor Introduction Working And Applications

Basics Of Brushless Dc Motors Bldc Motors Construction Working

Electrical Brushless Dc Motor Introduction Working And Applications

Faq What Are Hall Effect Sensors And What Is Their Role In Dc Motors

What Is A Brushless Dc Motor Aspina

Brushless Dc Motor Animation Youtube

Detailed Brushless Dc Motor Working Principle And Applications

Engineer It Understanding Basic Sensored Bldc Motor Operation Youtube

Brushed Vs Brushless Motors Operation Construction And Applications

Equivalent Circuit Diagram Of Dc Motor According To Working Principle Download Scientific Diagram

What Is Bldc Ceiling Fan And How It Works

Brushless Dc Motor Its Working And Advantages lc Motor

Controlling Bldc Motors Renesas

Brushless Dc Motor Brushless Dc Bldc Motor Microchip Technology

Choosing The Right Motor For Your Project Dc Vs Stepper Vs Servo Motors Latest Open Tech From Seeed Studio

How Do Brushless Hub Motors Work Explain That Stuff

Dc Motor Working Principle Lessons Blendspace

What Is Brushless Dc Motor Bldc Construction Working Electric Motor Generator Motor Generator Electronics Basics

Brushless Dc Motor Construction Working Principle And Advantages In Single Simple Words Principles

How Cpu Fan Works Bldc Motor Etechnog

Brushless Dc Motor Electric Motor Electric Power

Pdf Implementation Of A Three Phase Inverter For Bldc Motor Drive

Brushless Dc Motor Brushless Dc Bldc Motor Microchip Technology

Describe The Working Principle Of The Brushless Dc Motor From The Basics Programmer Sought

Controlling Bldc Motors Renesas

How Brushless Motors Work Bldc Motors

Brushless Dc Motors Part Ii Control Principles Edn

Why And How To Control Brushless Dc Motors Digikey

Basics Of Brushless Dc Motors Bldc Motors Construction Working

Controlling Bldc Motors Renesas

Wirtualne Laboratorium Energoelektronicznych Ukladow Napedowych

Brushless Dc Motor How It Works Ato Com

How Does A Bldc Motor Works Quora

How Brushless Motor And Esc Work Laptrinhx

Green Energy Wind Turbine Permanent Magnet Dc Motors

Basics Of Brushless Dc Motors Bldc Motors Construction Working

Www Infineon Com Dgdl Infineon Motorcontrol Handbook Additionaltechnicalinformation V01 00 En Pdf Fileid 5546d4626bb628d7016be6a9aa637e69

How Brushless Motor And Esc Work Howtomechatronics

Brushless Dc Bldc Motor Construction And Working Electricaleasy Com

How Brushless Motor And Esc Work Howtomechatronics

What Is Brushless Dc Motor Bldc Construction Working

1

The Difference Between Brushed And Brushless Motors

What Is Brushless Dc Motor Bldc Construction Working

Brushless Motor Series Archives Unmanned Systems Source

Brushless Dc Motor How It Works Youtube

Brushless Dc Motor Construction Working Principle And Advantages

Difference Between Brushed Dc Motor And Brushless Dc Motor

Brushless Dc Motor Ac Motors Electronics Textbook

What Are Brushless Dc Motors Renesas

Brushless Dc Motors Applications Advantages And Controlling Ele Times

Mas 865 18 How To Make Something That Makes Almost Anything

Brushless Dc Motor Construction Working Principle And Advantages

Brushless Dc Motor

Brushless Dc Motors Bldc What Are They How Do They Work

Brushless Dc Motors Control How It Works Part 1 Of 2 Youtube

How Brushless Motor And Esc Work Howtomechatronics

What Is Brushless Dc Motor Bldc Construction Working