Brushless Dc Motor

Rs Pro Brushless Dc Motor 24 V 0 066 Nm 4500 Rpm 4mm Shaft Diameter Rs Components

Customized 10kw Bldc Motor Wholesale 10kw Dc Motor

Brushless Dc Motor How It Works Youtube

212 Brushless Motor Bldc For Quadcopter 1000 1400 1800 20 Kv At Rs 650 Piece Brushless Dc Motor Id

Planet Analog Brushless Dc Motor Systems For The Uninitiated

9000 Rpm 24v Small Brushless Dc Motor Ato Com

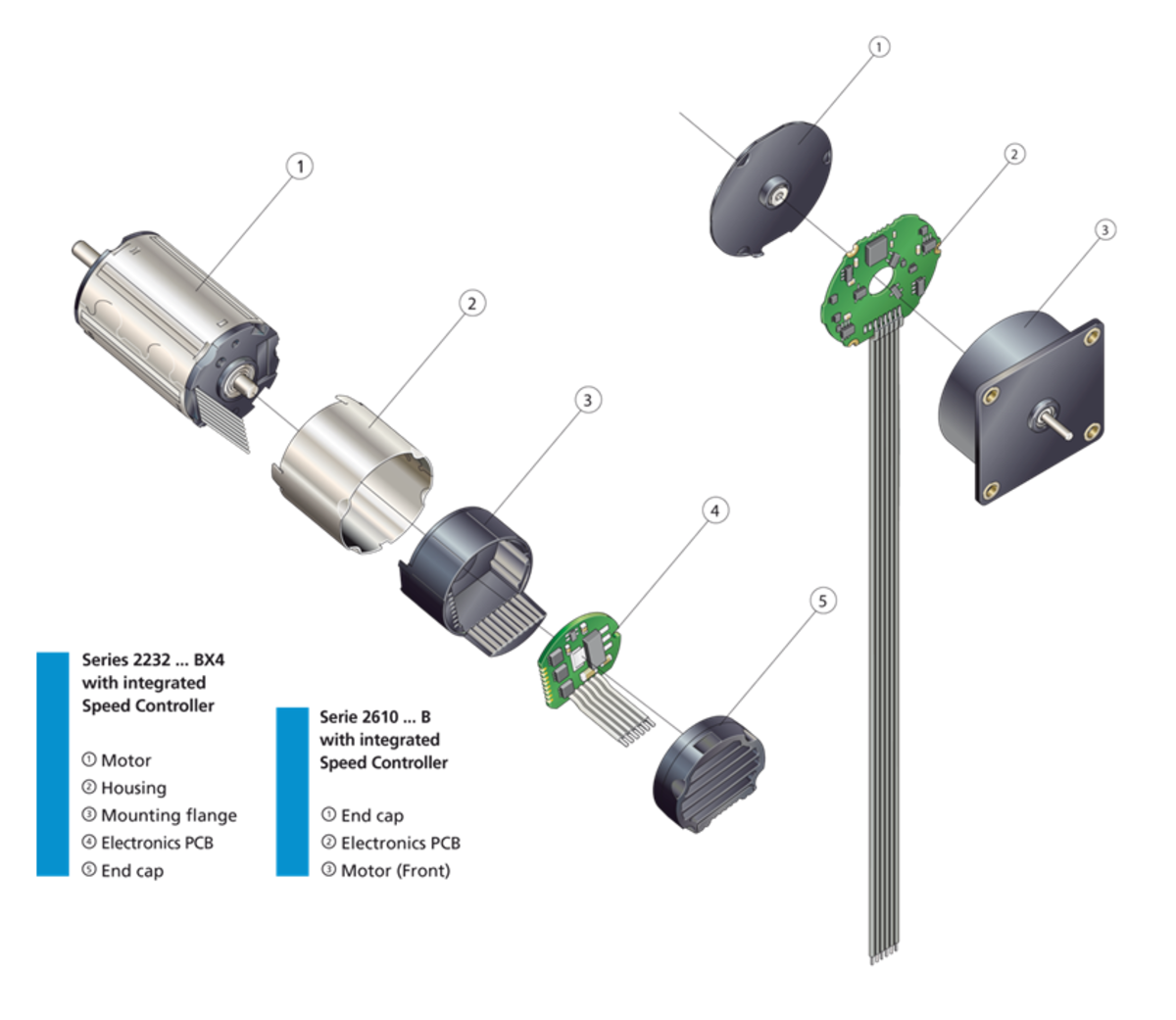

BMU Series Brushless DC Motors (BLDC Motors) (AC Input) The BMU Series features a compact, highpower and highefficiency brushless DC motor and is combined with an easy to use, easy to set speed controller The entire motor structure features our latest brushless DC motor technology and has been innovated in pursuit of the optimal performance.

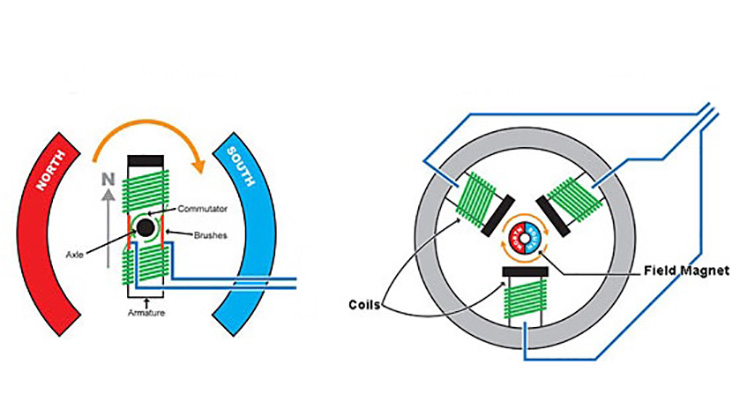

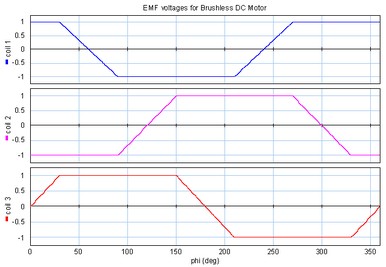

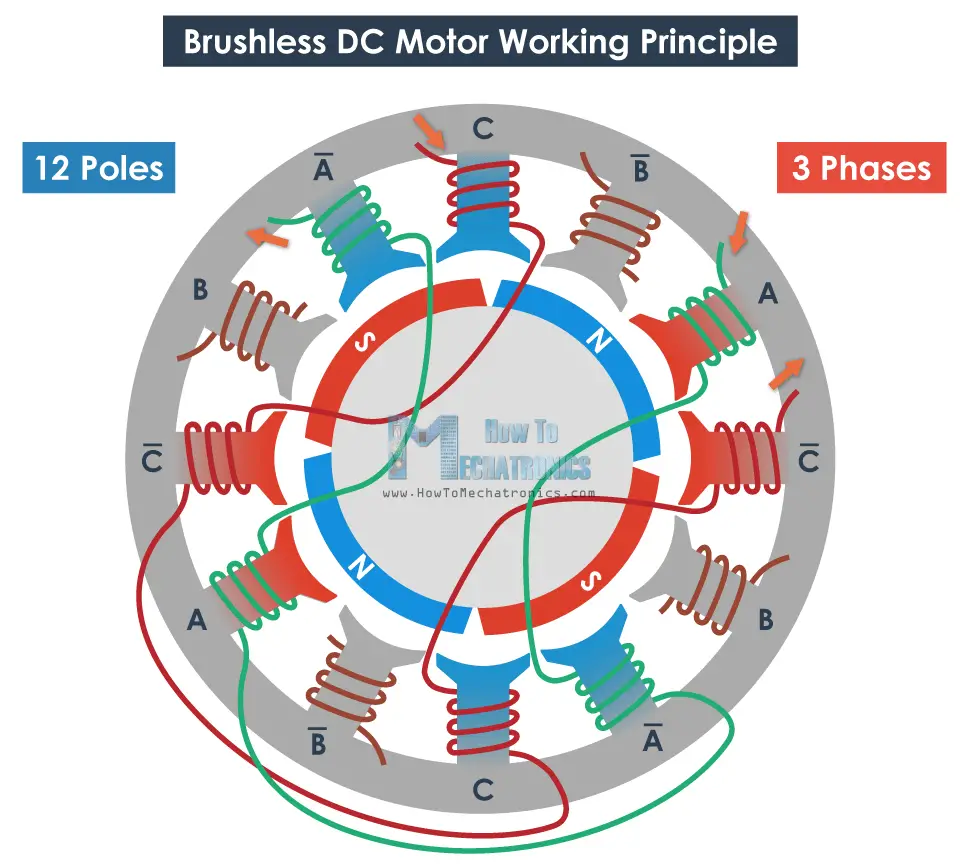

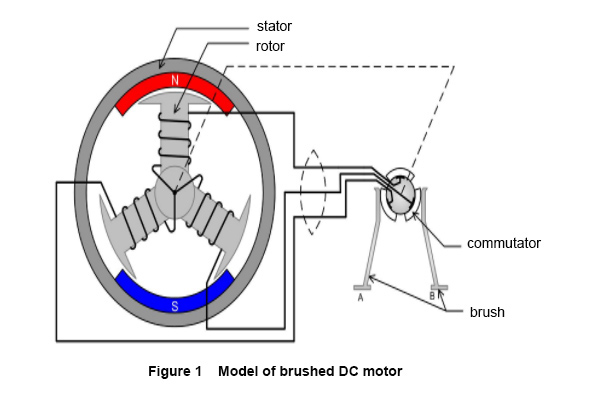

Brushless dc motor. The brushless DC (BLDC) motor’s increasing popularity is due to the use of electronic commutation This replaces the conventional mechanics comprised of brushes rubbing on the commutator to energize the windings in the armature of a DC motor. A brushless DC electric motor (BLDC motor or BL motor), also known as electronically commutated motor (ECM or EC motor) and synchronous DC motors, are synchronous motors powered by direct current (DC) electricity via an inverter or switching power supply which produces electricity in the form of alternating current (AC) to drive each phase of the motor via a closed loop controller. Brushless DC Motors are used for aircraft and ground vehicle applications This motor works efficiently with high power density by generating less noise and requires less maintenance rather than brushed DC motors For rotor assembly, they use permanent magnets It looks similar like AC motor with constant RPM and can be mass produced One has.

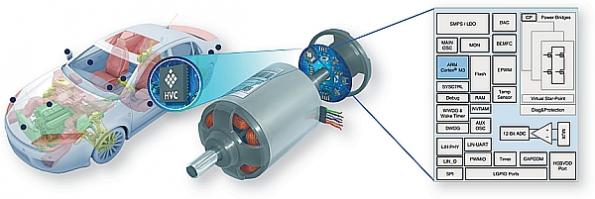

Brushless DC Motor, How it works ?. Get the best deals on Brushless Dc Motor when you shop the largest online selection at eBaycom Free shipping on many items Browse your favorite brands affordable prices. Today, a growing number of applications rely on a brushless DC (BLDC) motor, ranging from automotive to industrial applications Moreover, BLDC motors are used in medical equipment, home appliances, building controls and industrial automationIn each instance, a BLDC motor is chosen for the numerous advantages it offers, including.

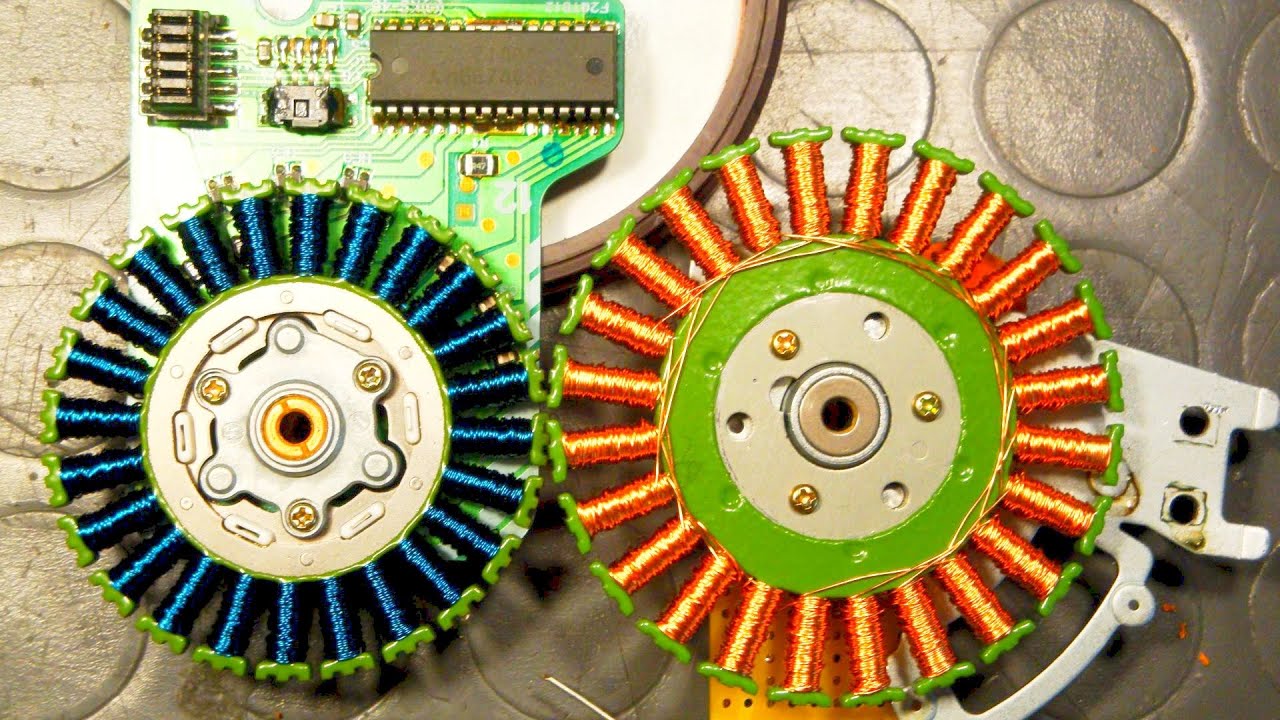

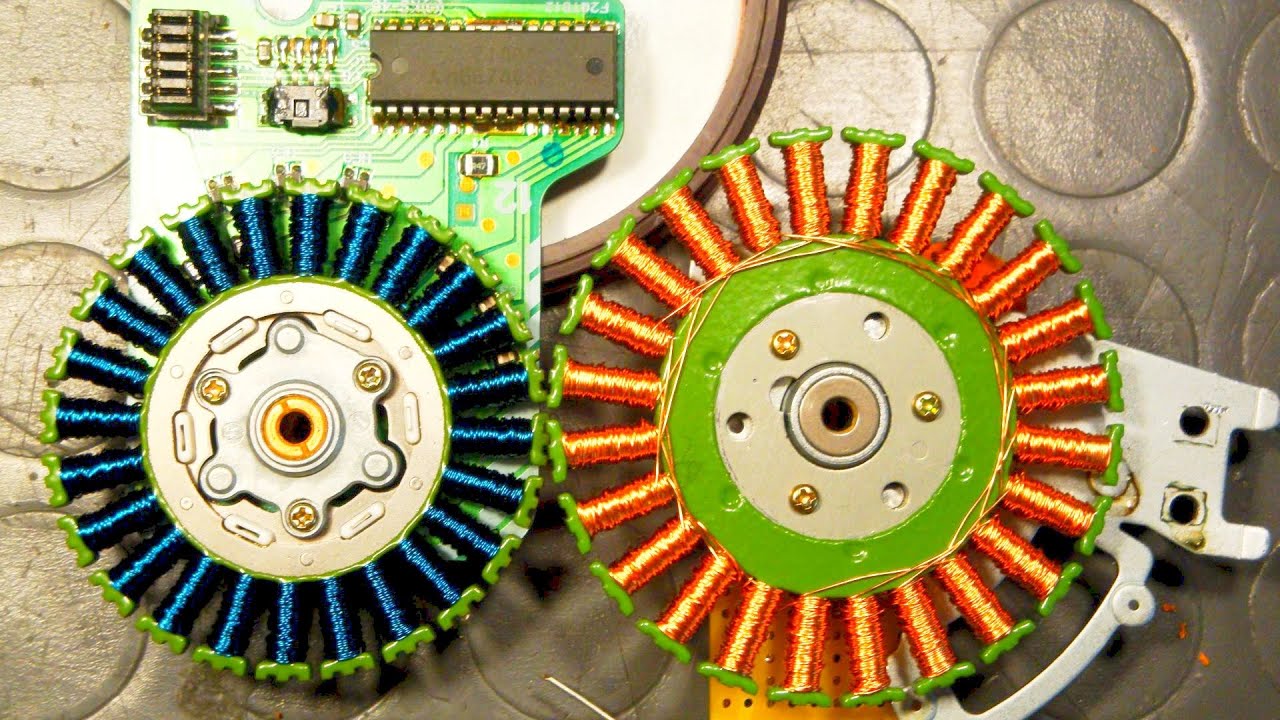

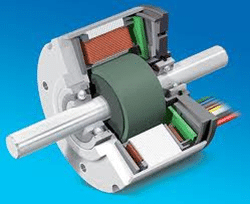

Direct Drive Brushless DC Torque Motors Moog has a variety of design options for standard motors For example, winding designs to modify torque sensitivity, back EMF, DC resistance and inductance in the event a power source (voltage or current) is limited. FAULHABER brushless flat DCmicromotors are 3phase, slotless, axial flux gap motors with a rotating back iron They have a much higher efficiency than other flat brushless motors and their rotating back iron provides a high rotor inertia that is ideal for applications requiring low torque ripple and very precise continuous speed control. DC Brushless Motor,12V 032A 150W RPM Electric Brushless DC Motor Large Torque High Power for Go Karts EBike Motorcycle 27 out of 5 stars 3 BGNing 212 1400kv Brushless Outrunner Motor 10t 30a Speed Controller ESC,Rc Aircraft Kk Quadcopter UFO.

FAULHABER brushless flat DCmicromotors are 3phase, slotless, axial flux gap motors with a rotating back iron They have a much higher efficiency than other flat brushless motors and their rotating back iron provides a high rotor inertia that is ideal for applications requiring low torque ripple and very precise continuous speed control. A brushless DC (BLDC) motor is highly reliable since it does not have any brushes to wear out and replace, brushless design for high speeds, long life and high power density ATO has a wide selection of low cost brushless DC motors including high torque and high RPM motors to meet your specific needs They come in different size to provide the right torque and speed for your application. The Bodine family of brushless DC inline planetary and parallel shaft gearmotors deliver torque from 58 to 350 lbin (40 Nm) Consisting of a brushless DC motor, a gearhead, a motor feedback device (encoder) and a control, our unique INTEGRAmotors combine the major elements of a motion control system in one compact package.

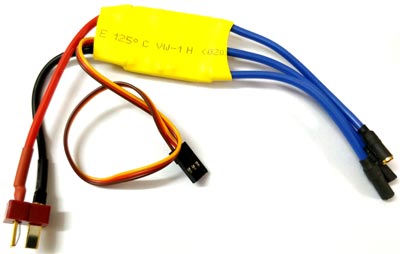

Brushless DC motors require specialized controllers and complicated control algorithms to operate correctly Expensive The cost of the motors themselves is not overly high, but when the cost of the controller is added as well, the overall cost of including a brushless DC motor into a project is relatively high. The brushless DC motor can be applied to wide range of applications, such as CNC machining, multijoint robot, constant speed control, tracking systems, XY (Z) platform, institutional positioning (fixed speed) control, torque control, automation and control. Make a Brushless DC Motor This video instructable will show you how to build a brushless DC motor with minimal tools and materials It can be done in an afternoon or less, and costs almost nothing (the materials are things that are on the edge of being garbage or not garbage.

Brushless DC motors are well suited for applications that require tight speed regulation, high speeds (we offer stock models up to 10K RPM), or where a brushtype DC motor would generate too much noise and wear out the brushes too quickly Examples include centrifuges, lens grinders and cooling fans in commercial cooking equipment. Brushless DC (BLDC) motor drivers from TI simplify industrial, automotive and functional safety applications Our 3phase brushless DC motor drivers offer the flexibility of integrated motor commutation logic or easily pair with external microcontrollers for sensored and sensorless BLDC motor control. Some servomotor systems use brushless dc motors instead of other types of motors (either a brushed DC motor or an AC motor such as an induction motor) BLDC motors are used in everything from lowpower applications such as consumer products to high power applications in electric vehicles and industrial equipment.

Today, a growing number of applications rely on a brushless DC (BLDC) motor, ranging from automotive to industrial applications Moreover, BLDC motors are used in medical equipment, home appliances, building controls and industrial automationIn each instance, a BLDC motor is chosen for the numerous advantages it offers, including. Get the best deals on Brushless Dc Motor when you shop the largest online selection at eBaycom Free shipping on many items Browse your favorite brands affordable prices. Brushless DC motors Electronically commuted 3phase motors (EC motors) are especially well suited for applications requiring quiet running characteristics and a long service life The highenergy permanent magnets allow high acceleration rates, combined with very high efficiency and speeds of up to 14,000 rpm.

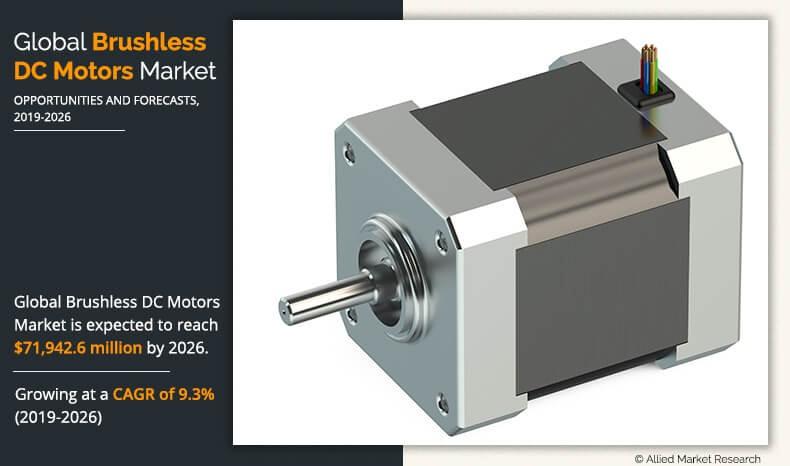

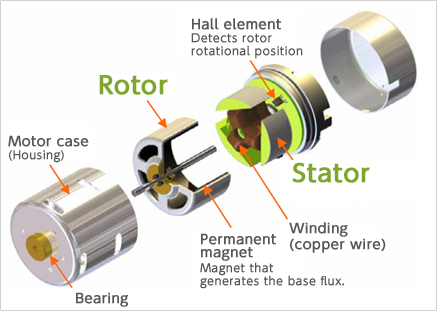

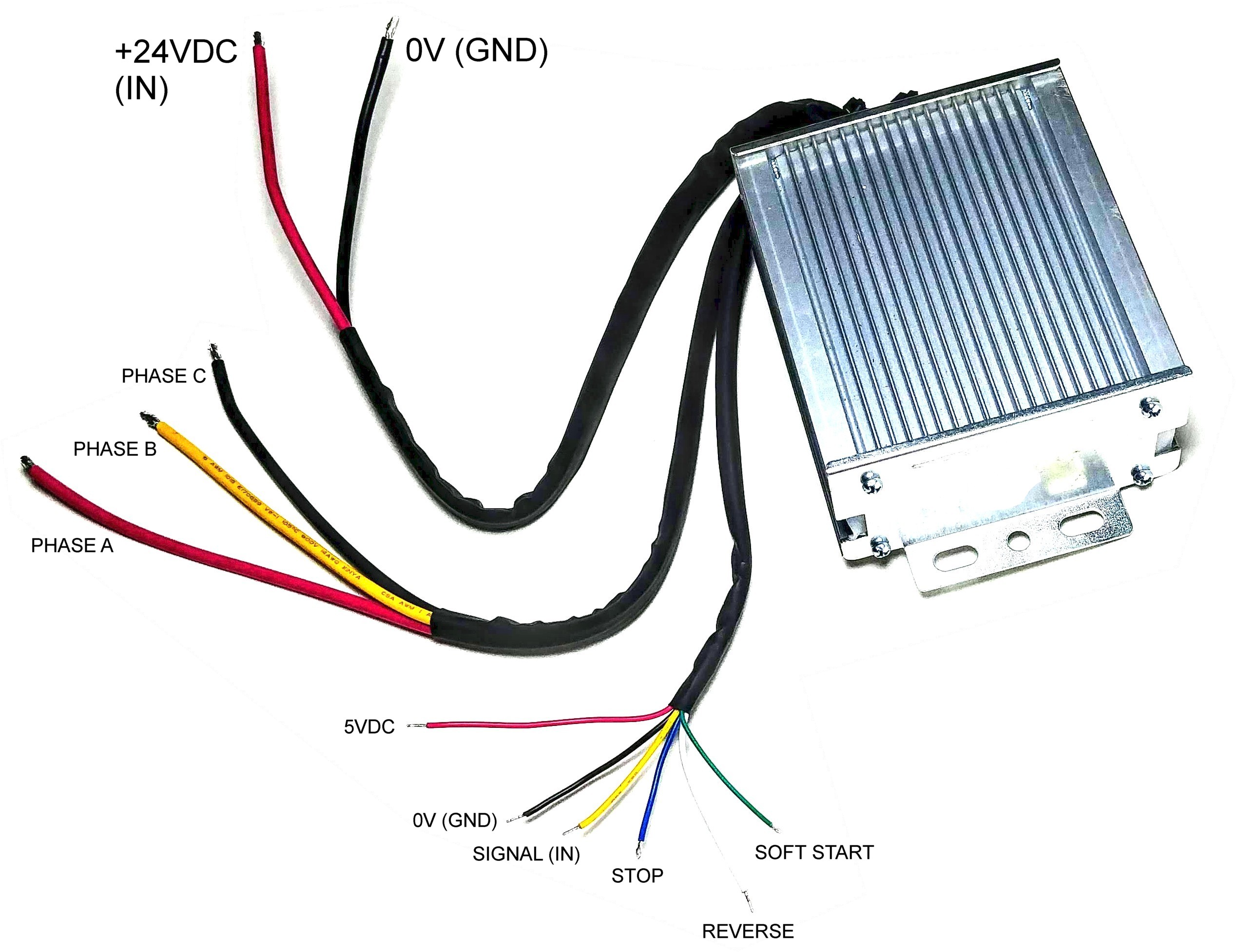

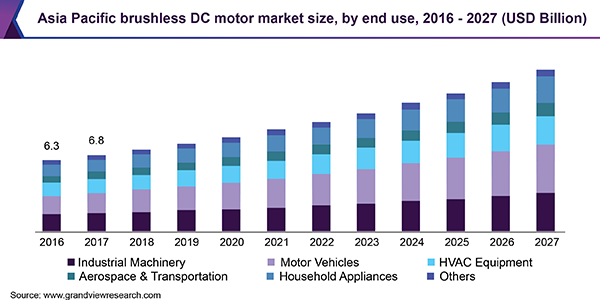

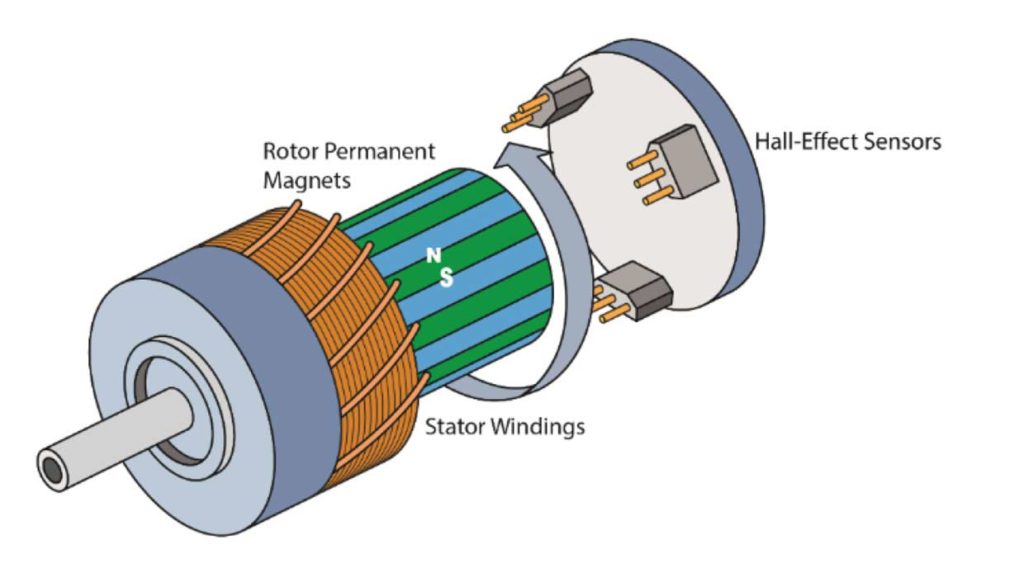

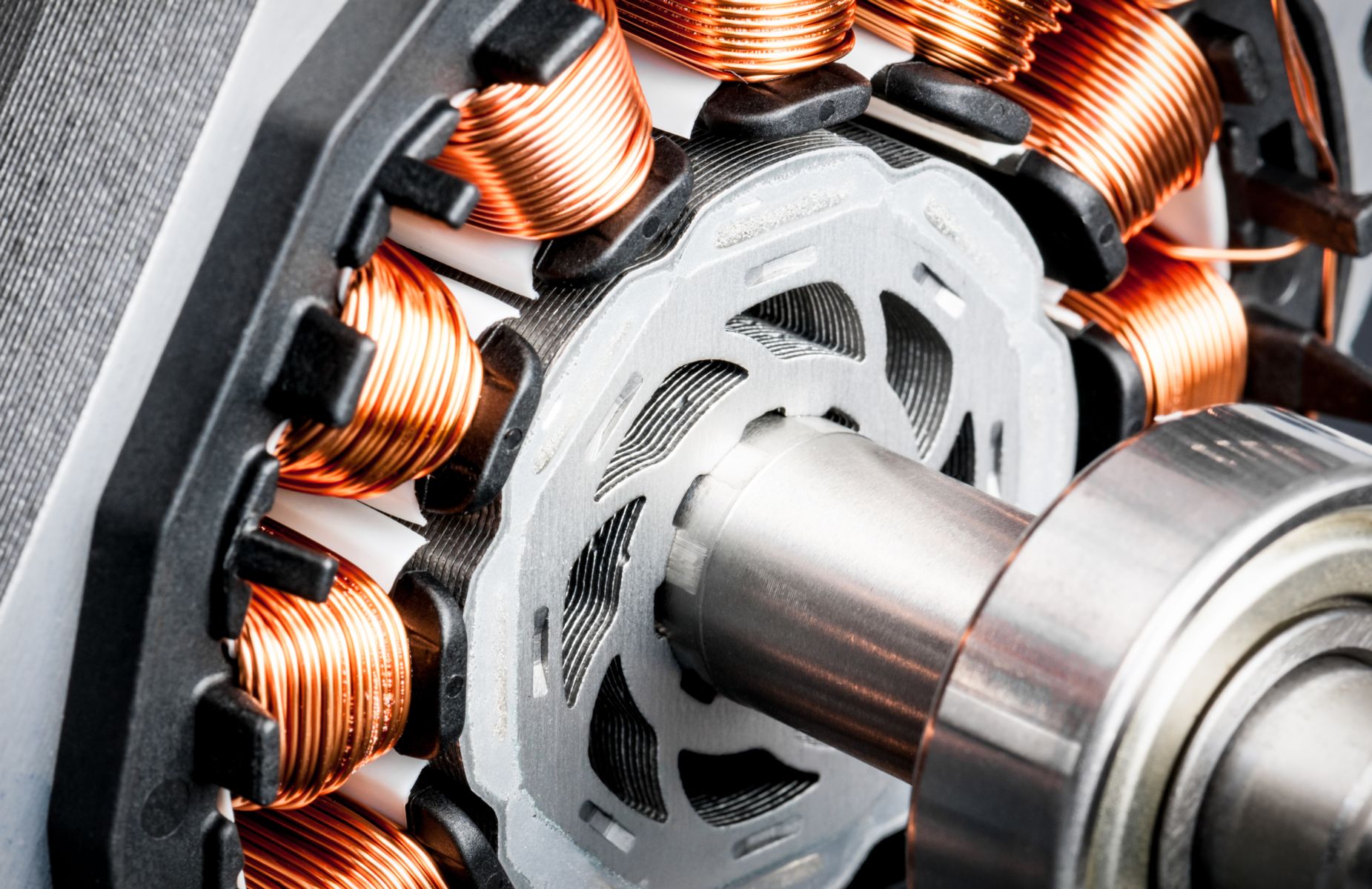

The brushless DC motor is driven by an electronic drive that switches the supply voltage between the stator windings as the rotor turns The rotor position is monitored by the transducer (optical or magnetic) which supplies information to the electronic controller and based on this position, the stator winding to be energized is determined. Brushless DC Motor Let's make an electric motor that spins using neodymium magnets and wire This shows how an electric current is converted into motion We’re building a primitive brushless DC motor It’s not going to win any efficiency or design awards, but we lik. The global brushless DC motors market size is expected to reach $71,9426 million in 26, from $34,1535 million in 18, growing at a CAGR of 93% from 19 to 26 In 18, inner rotor.

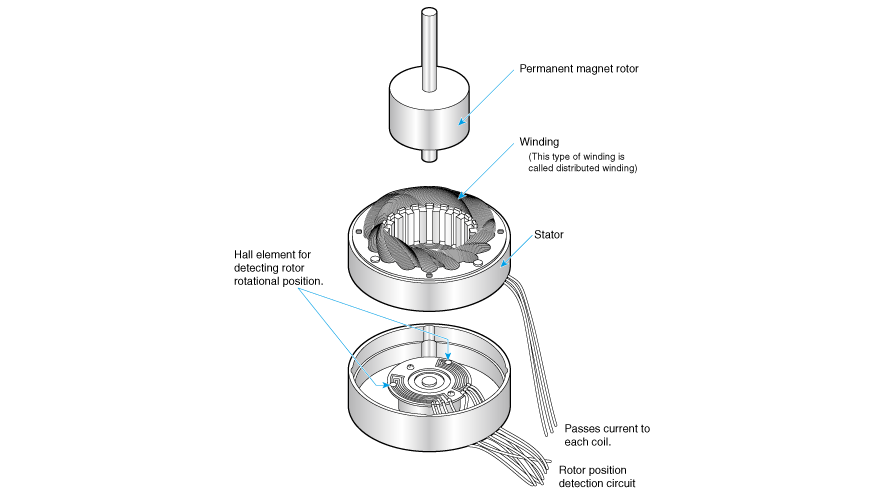

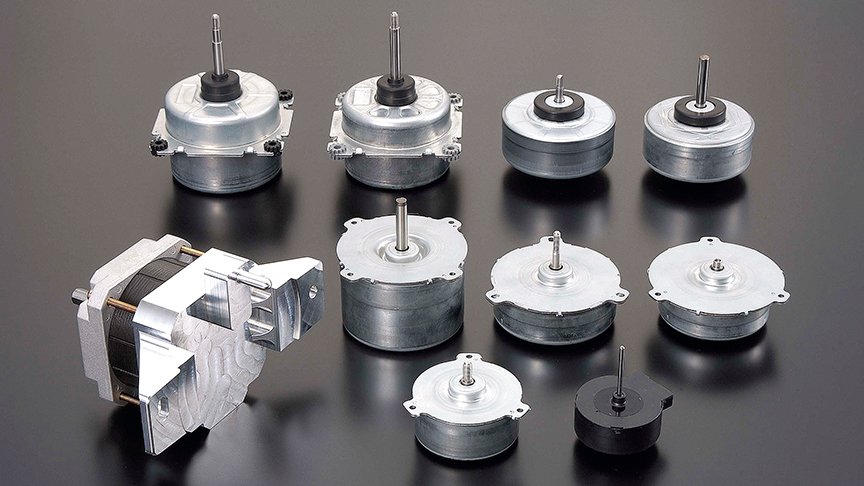

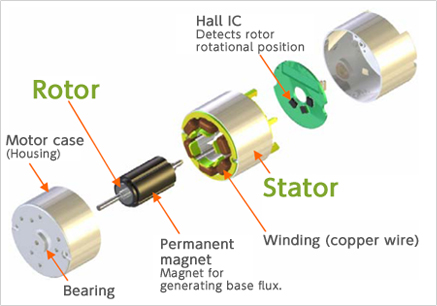

A motor converts supplied electrical energy into mechanical energy Various types of motors are in common use Among these, brushless DC motors (BLDC) feature high efficiency and excellent controllability, and are widely used in many applications The BLDC motor has powersaving advantages relative to other motor types. Electrical equipment often has at least one motor used to rotate or displace an object from its initial position There are a variety of motor types available in the market, including induction motors, servomotors, DC motors (brushed and brushless), etc Depending upon the application requirements, a particular motor can be selected. Brushless DC motors typically have an efficiency of 8590%, while brushed motors are usually only 7580% efficient Brushes eventually wear out, sometimes causing dangerous sparking, limiting the lifespan of a brushed motor Brushless DC motors are quiet, lighter and have much longer lifespans Because computers control the electrical current.

BMU Series Brushless DC Motors (BLDC Motors) (AC Input) The BMU Series features a compact, highpower and highefficiency brushless DC motor and is combined with an easy to use, easy to set speed controller The entire motor structure features our latest brushless DC motor technology and has been innovated in pursuit of the optimal performance. Brushless DC motors are well suited for applications that require tight speed regulation, high speeds (we offer stock models up to 10K RPM), or where a brushtype DC motor would generate too much noise and wear out the brushes too quickly Examples include centrifuges, lens grinders and cooling fans in commercial cooking equipment. Brushless DC motors can provide maximum torque continuously during rotation, while brushed DC motor can provide maximum torque at an only specific point of the rotation For the same torque rating, the brushed motor will require a much bigger magnet as compared to the brushless DC motor.

Brushless DC Motors or BLDC Motors have become a significant contributor of the modern drive technology Their rapid gain in popularity has seen an increasing range of applications in the fields of Consumer Appliances, Automotive Industry, Industrial Automation, Chemical and Medical, Aerospace and Instrumentation. Brushless DC Motors and other robot products At RobotShop, you will find everything about robotics RobotShop is in full operation & shipping globally while adhering to strict safety protocol Fighting COVID19 together!. BMU Series Brushless DC Motors (BLDC Motors) (AC Input) The BMU Series features a compact, highpower and highefficiency brushless DC motor and is combined with an easy to use, easy to set speed controller The entire motor structure features our latest brushless DC motor technology and has been innovated in pursuit of the optimal performance.

Anaheim Automation's Brushless DC Motor products are designed for highvolume OEM applications with low cost being the primary objective These highquality BLDC Motor product lines come in a compact package with high power density Our round or square flange brushless motors are available in twelve sizes from 03" to 48" in diameter, from. Any motion control expert should understand the difference between brushed and brushless DC motors Brushed motors were once very common Though they’ve been largely supplanted by their brushless counterparts, the right DC motor of either type can make a project far more efficient. The global brushless DC motors market size is expected to reach $71,9426 million in 26, from $34,1535 million in 18, growing at a CAGR of 93% from 19 to 26 In 18, inner rotor.

DC motor and control assemblies are for use on constant or diminishing torque applications such as a conveyor belt Stepper motors can run for a specific interval, or step, allowing them to start, stop, and reverse direction Hazardous location DC motors are for use in locations where hazardous vapors or combustible dusts are present. A brushless DC motor (also known as a BLDC motor or BL motor) is an electronically commuted DC motor which does not have brushes The controller provides pulses of current to the motor windings which control the speed and torque of the synchronous motor. Motor Brushless Controller, 36V/48V 1000W Brushless DC Motor Controller Motor Sine Wave Controller for Electric Bike Bicycle Ebike Scooter Brand WonVon 38 out of 5 stars 27 ratings Price $4999 & FREE Shipping Details & FREE Returns Return this item for free.

BMU Series Brushless DC Motors (BLDC Motors) (AC Input) The BMU Series features a compact, highpower and highefficiency brushless DC motor and is combined with an easy to use, easy to set speed controller The entire motor structure features our latest brushless DC motor technology and has been innovated in pursuit of the optimal performance. Today, a growing number of applications rely on a brushless DC (BLDC) motor, ranging from automotive to industrial applications Moreover, BLDC motors are used in medical equipment, home appliances, building controls and industrial automationIn each instance, a BLDC motor is chosen for the numerous advantages it offers, including. Brushless DC (BLDC) motor drivers from TI simplify industrial, automotive and functional safety applications Our 3phase brushless DC motor drivers offer the flexibility of integrated motor commutation logic or easily pair with external microcontrollers for sensored and sensorless BLDC motor control.

A brushless DC (BLDC) motor is highly reliable since it does not have any brushes to wear out and replace, brushless design for high speeds, long life and high power density ATO has a wide selection of low cost brushless DC motors including high torque and high RPM motors to meet your specific needs They come in different size to provide the right torque and speed for your application. The brushless DC motor is driven by an electronic drive that switches the supply voltage between the stator windings as the rotor turns The rotor position is monitored by the transducer (optical or magnetic) which supplies information to the electronic controller and based on this position, the stator winding to be energized is determined. Make a Brushless DC Motor This video instructable will show you how to build a brushless DC motor with minimal tools and materials It can be done in an afternoon or less, and costs almost nothing (the materials are things that are on the edge of being garbage or not garbage.

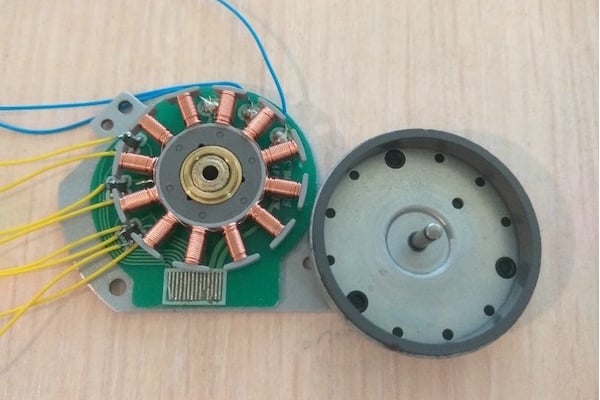

ElectroCraft Brushless DC Motors (BLDC) are designed for high performance BLDC motors are ideal for applications where rapid acceleration and high accuracy are called for ElectroCraft Rapid Power and Rapid Power Plus BLDC motors have an efficient, compact design, with high torque density defined by high torque relative to frame size. The spinning part of an electric motor is called the rotor Most brushless motors have permanent magnets on the rotor Our rotor spins thanks to a 608ZZ bearing stuck on a pencil This bearing is commonly used in things like skateboard wheels and fidget spinners. August 19, 13 In order to make the operation more reliable, more efficient, and less noisy the recent trend has been to use brushless DC (BLDC) motors They are also lighter compared to brushed motors with the same power output This article gives an illustrative introduction on the working of BLDC motors.

Brushless DC motors from Oriental Motor can achieve up to 5159 lbin of torque when combined with a standard geared option Their space saving design contributes to a compact and powerful solution ranging from 15 W up to 400 W Their flat torque characteristics can produce the same rated torque at wide speed range. A brushless DC electric motor (BLDC motor or BL motor), also known as electronically commutated motor (ECM or EC motor) and synchronous DC motors, are synchronous motors powered by direct current (DC) electricity via an inverter or switching power supply which produces electricity in the form of alternating current (AC) to drive each phase of the motor via a closed loop controller. How Brushless Motors Work A brushless motor loses the brushes and the commutator And the locations of the magnets and windings are reversed The magnets are on the conventional motor shaft and.

Browse Pittman Motors' wide variety of Brushless DC also known as BLDC motors. In a brushless DC motor (BLDC), you put the permanent magnets on the rotor and you move the electromagnets to the stator Then you use a computer (connected to highpower transistors) to charge up the electromagnets as the shaft turns This system has all sorts of advantages. An allinone solution for precise positioning, these motors are often used to move CNC heads and other automated systems Connect to a computer with the included cable to program them— they can store up to 16 settings Also known as stepper motors, they turn their shaft in small increments (steps) Motors with a sensor and encoder track how far the shaft rotates and signals to the driver.

Brushless DC motors with flat design Ø 92 – 90 mm, 02 – 260 W Top performance, attractive prices Flat motors are available with Hall sensors and integrated electronics For product details & specifications Online Shop. Motor Brushless Controller, 36V/48V 1000W Brushless DC Motor Controller Motor Sine Wave Controller for Electric Bike Bicycle Ebike Scooter Brand WonVon 38 out of 5 stars 27 ratings Price $4999 & FREE Shipping Details & FREE Returns Return this item for free. The brushless DC (BLDC) motor’s increasing popularity is due to the use of electronic commutation This replaces the conventional mechanics comprised of brushes rubbing on the commutator to energize the windings in the armature of a DC motor.

A brushless DC motor (known as BLDC) is a permanent magnet synchronous electric motor which is driven by direct current (DC) electricity and it accomplishes electronically controlled commutation system (commutation is the process of producing rotational torque in the motor by changing phase currents through it at appropriate times) instead of a. Allied Motion currently offers two types of brushless DC motors without integrated controller electronics the Globe INB/NB line of small frame, rareearth brushless DC motors and the ResMax high speed brushless DC motors designed to power medical respirators The Overview & Selection Guide allows you to review 13 different Brushless motor types. Today, a growing number of applications rely on a brushless DC (BLDC) motor, ranging from automotive to industrial applications Moreover, BLDC motors are used in medical equipment, home appliances, building controls and industrial automationIn each instance, a BLDC motor is chosen for the numerous advantages it offers, including.

RobotShop is in full operation & shipping globally while adhering to strict safety protocol. Some servomotor systems use brushless dc motors instead of other types of motors (either a brushed DC motor or an AC motor such as an induction motor) BLDC motors are used in everything from lowpower applications such as consumer products to high power applications in electric vehicles and industrial equipment. Brushed DC motors depend on a mechanical system to transfer current, while AC and brushless DC gear motors use an electronic mechanism to control current The brushed motors have a wound armature attached to the center with a permanent magnet bonded to a steel ring surrounding the rotor.

55HP 48V High Power Brushless DC Motors, be designed to operate in a voltage range from 24V to 380V DC, its outer diameter is 180mmThe Series BLDC154 motors cover a output power range from 15KWto 10KW, its torque range on continuous duty is 3Nm,on intermittent duty up to 7550NmIt can keeps at a high efficiency at wide speed range.

Rs Pro Brushless Dc Motor 36 V 0 68 Nm 4000 Rpm 8mm Shaft Diameter Rs Components

Brushless Dc Motor Basics Motion Control Blog

Brushless Dc Motor Tester For E Bike E Scooter

Brushless Dc Motor Market Size Share Analysis Report 25

Brushless Motors Faulhaber

How A Brushless Dc Motor Works Custom Maker Pro

Brushless Dc Motor Market Size Share And Growth Forecast By 26

Slotless Versus Slotted Brushless Dc Motors

Pdf Design Of A Brushless Dc Bldc Motor Controller

Brushless Dc Motor Market Forecast Trend Analysis Competition Tracking Global Market Insights 19 To 29

Construction Of Bldc Motor Motor Generator Electric Motor For Car Electric Motor Generator

What Are Brushless Dc Motors Renesas

What S The Difference Between An Ec Motor And A Bldc Motor

24v 3500rpm 0 6nm 2w 14 0a F57xmm Brushless Dc Motor

Brushless Dc Motor For Demanding Operating Room Applications Power Electronics

How To Power And Control Brushless Dc Motors Digikey

Brushless Dc Motors And Brushed Dc Motors Explained Bldc Fan 2 Youtube

Dys Electronic Speed Controller Esc For Brushless Dc Motor Quad Rotor Quad Copter 30amp Make Dys Amazon In Industrial Scientific

What Is Brushless Dc Motor Bldc And How To Control Bldc Motor With Arduino

Mophorn 1800w Electric Brushless Dc Motor Kit 48v 50rpm Brushless Motor With 32a Speed Controller And Throttle Grip Kit For Go Karts E Bike Electric Throttle Motorcycle Scooter Amazon Com

Brushless Dc Motors With Integrated Speed Controller

Brushless Motors Nidec Corporation

Engineered To Order Bldc Motors Generators And Brushless Dc Alternators Duryea Technologies

Pn 24c Brushless Bldc 24v Motor Driver Speed Controller 17a Makermotor

Brushless Dc Motors Introduction For Next Generation Missile Actuation Systems Outline Analog Devices

Q Tbn And9gcstnh5d1iacmygrpd5dzfbsbzthkafjmqsdz91tbikibx8rvez1 Usqp Cau

Brushless Motors Faulhaber

Motor Wires Cable For 500 600w Brushless Dc Motor 3 2 0mm Motor Phase 5pcs Hall Sensor Wires Cable Wire Sleeve Cable Wire Labelswire Excavator Aliexpress

Bldc Motor Control Power Electronics And Drives Pantech Blog

Brushless Dc Motors And Brushed Dc Motors What Are The Differences Insight Solutions Global

1

Brushless Dc Motors Market Size Industry Report 27

Brushless Dc Motors Control How It Works Part 1 Of 2 Youtube Motor Electronics Basics Electronics Mini Projects

2 2 1 What Is A Brushless Dc Motor Nidec Corporation

Brushless Dc Motor Construction Working Principle And Advantages

Brushless Dc Electric Motor Wikipedia

What S The Difference Between Brush Dc And Brushless Dc Motors Electronic Design

Brushed Dc Motors Vs Brushless Dc Motors Motion Control Blog

Choosing Between Brush And Brushless Dc Motors Allied Motion

Sim Webhelp Toolboxes Mechatronics Toolbox Servo Motor Editor Theory Basic Principles Brushless Dc Motors

Electromagnetic Phenomena Analysis In Brushless Dc Motor With Speed Control Using Pwm Method In Open Physics Volume 15 Issue 1 17

Brushless Dc Motor Phidget Dcc1100 0 At Phidgets

Thank Goodness For Brushless Dc Motors

1

Brushless Dc Motor With A Multirotor Propeller Download Scientific Diagram

60w 1500 3000 Rpm 24v Bldc Motor With Controller Bldc Motor Tachometric Controls Pune Id

Brushless Dc Motors With Drives Integrated Electronics Allied Motion

Electromen Em 240 Brushless Dc Motor Controller 12 24v 1 5a

Brushless Dc Motor Autodesk Online Gallery

The Basics Of Bldc Motors Elettroamici

Make A Brushless Dc Motor 3 Steps Instructables

Bldc Brushless Dc Motor And Slipring Arduino Project Hub

Dys Brushless Dc Motor 1800 Kv For Quadcopters Or Multirotors Sparkpcb Com

Brushless Motors For Better Results Lower Maintenance Powertech Review Indian Electrical Magazine Power Industry Magazine Renewable Energy Magazine Solar Magazine

Brushless Dc Motor Fed By Six Step Inverter Matlab Simulink Mathworks Benelux

Moons Ech260 High Speed Slotless Brushless Dc Motors High Speed Slotless Bldc Motor Up To 150w Small Size High Torque By Moons

Brushless Dc Motor For Quadcopter 1500kv Bldc Motor Brushless Direc Current Motor ब रशल स ड स म टर Robomart Noida Id

Buy Combo Of 212 1000kv Bldc Motor With Simonk 30a Esc And 1045 Propellers

Apba60 Brushless Motors 400 W 60 Mm Flange Nanotec

Reichelt Nl

Q Tbn And9gct8yrmsg08m9qhkw2cvrflwxt1ebal0s Bexkjlsl3xojz3jyfp Usqp Cau

How Brushless Motor And Esc Work Howtomechatronics

Discrete Time Brushless Dc Motor Current Pi Controller Simulink

Buy 212 1000kv Bldc Motor Online At The Best Price In India

How To Power And Control Brushless Dc Motors Digikey

Xcluma 212 20 Kv 6t Brushless Dc Motor Rc Airplanes Quadcopter Amazon In Industrial Scientific

High Power High Torque 48v 4kw Bldc Motor 4000w Heavy Duty 48v Brushless Dc Motor Dc Motor Aliexpress

Ac7 Sensorless Brushless Dc Motor Drive During Speed Regulation Matlab Simulink

E Bike Brushless Dc Geared Motor 1418zxf 48v 450rpm 500w Premium Quality Rki 9004 3 690 00 Robokits India Easy To Use Versatile Robotics Diy Kits

China 36mm Brushless Dc Motor 12v Or 24v 5w 25w China Brushless Dc Motor Dc Motor

Brushed Dc Motor Vs Brushless Dc Motor Ato Com

Rc Brushless Dc Motor Esc Mbed

Brushless Dc Motors Geeplus Com

Buy 212 1000kv Bldc Motor With Simonk 30a Esc Online

Brushless Dc Motor Design Portescap

Ametek Mae Brushless Dc Motor Bldc Bl5556 Ebay

Brushless Dc Motors Bldc Motors Sinotech Specifications

Evaluating Brushless Dc Motors In Electric And Electric Hybrid Vehicles Yokogawa

Brushless Dc Motors Bldc Motors From Manufacturer Nanotec

Brushless Dc Bldc Motor Construction And Working Electricaleasy Com

Bxm6400 Gfs Oriental Motor Brushless Dc Motor Valin

Brushless Dc Electric Motor Wikipedia

How To Cost Effectively Transition To Brushless Dc Motors For Your Applications

What Is A Brushless Dc Motor Aspina

Xsaqjngjr6f4hm

Motor Control Brushless Dc Bldc Farnell

Wooow 48v To 64v 800w Brushless Dc Motor Controller Run Bldc Motors Without Hall Sensor Youtube

Brushless Dc Motor

Brushless Dc Motors Gain In Popularity Ee Publishers

5000 Rpm Brushless Dc Motor Disc Motor Science Toy Enginediy Enginediy

An Introduction To Brushless Dc Motors Motion Control Blog

What Do Design Engineers Need To Know About Brushless Dc Motor Technologies

Rpm 12v 24v Small Brushless Dc Motor Ato Com

3 Phase Brushless Dc Motor Control With Hall Sensors Industry Articles

Wish

Brushless Motors Nidec Corporation

Brushless Dc Motor Market Size Share Analysis Report 25

Brushless Dc Motors Bldc Isl Products International

Vexta Brushless Dc Motor Bl215gd Af 15w 3000 Rpm Bl215gdaf For Sale Online

Absolute Position Sensing The Key To Better Brushless Dc Motor Control Electronic Products